How does Exponent's multidisciplinary approach provide better process evaluations and quality control audits?

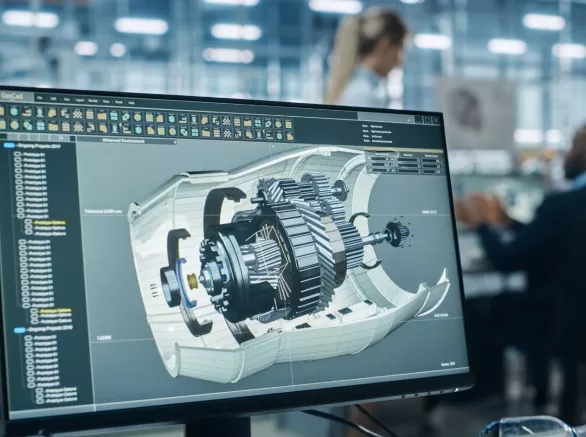

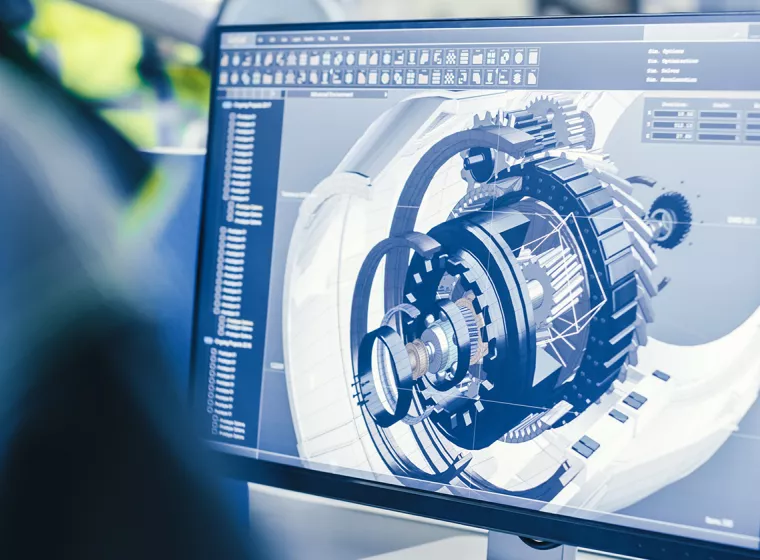

When clients face issues with their final products or if manufacturing machinery goes offline, clients turn to Exponent for rapid response and a value-driven approach. Our electrical engineers, computer scientists, data scientists, mechanical engineers, and manufacturing experts work to determine root causes of failures, assess process control and quality control, and evaluate supply chains — examining every angle for accurate understanding.

How can our value-driven, process-oriented focus help you improve performance and product quality?

With more than 50 years in failure analysis, Exponent's auditing programs are designed to help you improve the performance of the process and quality of your product while minimizing the risk of failures.

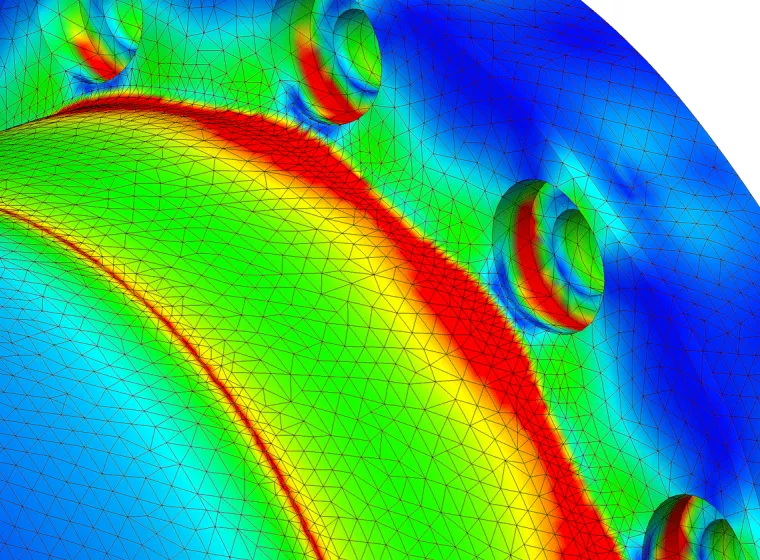

Our engineers have a strong background in ISO 9001 auditing techniques and principles and will help you develop best practices. But what enables Exponent to provide unparalleled value is our knowledge of how products fail in the field and how the manufacturing process can contribute to such failures. Our audits have a process-oriented focus — where the root of most manufacturing problems occurs — and target the quality systems associated with the process.

Gain peace of mind with our on-site investigations and factory audits.

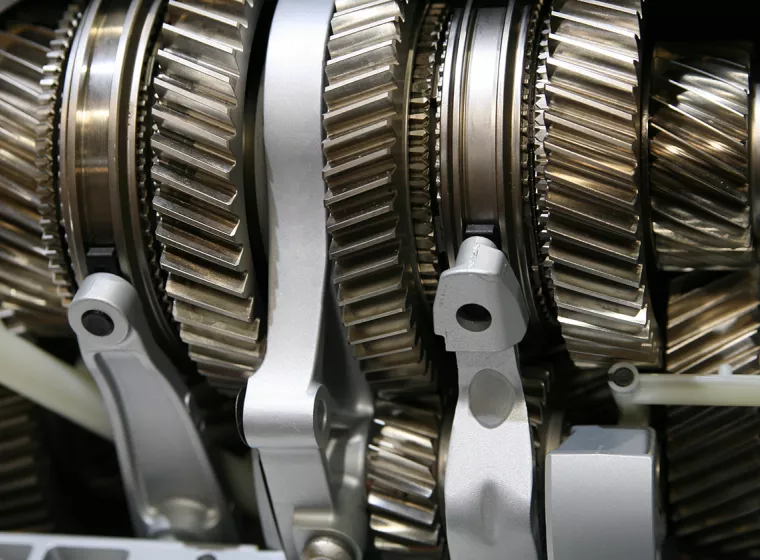

Exponent conducts engineering audits of manufacturing facilities to help ensure suppliers follow best practices in manufacturing processes and quality control. In addition to full factory audits, which include an evaluation of the entire manufacturing process from incoming material quality control (IQC) to outgoing quality control (OQC), Exponent frequently visits manufacturing lines as part of our root-cause analysis investigations.

By examining various manufacturing and handling processes, we can assess whether contamination, mechanical defects, tolerance errors, and physical and chemical control parameter settings could have contributed to failures.

We have experience working with many different types of products, including but not limited to:

Battery cell (a range of chemistries)

Battery pack assembly

Connectors

Capacitors

Inductors

Resistors

Varistors

Flip chips

Clean room evaluation

Semiconductor fabs

PCB/PCBA

Ambient light sensor plating

LED and LCD displays

Adhesive application and curing

Metal forming

Metal casting

Polishing/grinding/finishing

Surface treatment

Anodization

System assembly

Injection molding

Capabilities & Services

Our Capabilities Are Unparalleled

With expertise in over 90 disciplines and hundreds of capabilities, tools, and methodologies — we get to the root of even the most complex challenges and give you the objective answers you need.

Experts

Our global and comprehensive expertise across industries gives us a deep understanding of current challenges, best industry practices, and the implications of emerging technologies.

Practice Director and Principal Scientist

Director of Asia Offices and Principal

![Factory Auditing & Assembly Line Evaluations [ME]](/sites/default/files/styles/hero_purple/public/media/images/GettyImages-1320492982.jpg.webp?itok=OfMmm6Rs)

![Mechanical Failure Analysis [ME]](/sites/default/files/styles/item_accordion/public/media/images/GettyImages-1136840043.jpg.webp?itok=dMroZAZf)

![Risk & Safety Analysis [ME]](/sites/default/files/styles/item_accordion/public/media/images/GettyImages-528181173.jpg.webp?itok=M6lnHV48)

![Factory Auditing & Assembly Line Evaluations [ME]](/sites/default/files/styles/cards_home_card/public/media/images/GettyImages-1320492982.jpg.webp?itok=yHRcmsIH)