February 4, 2025

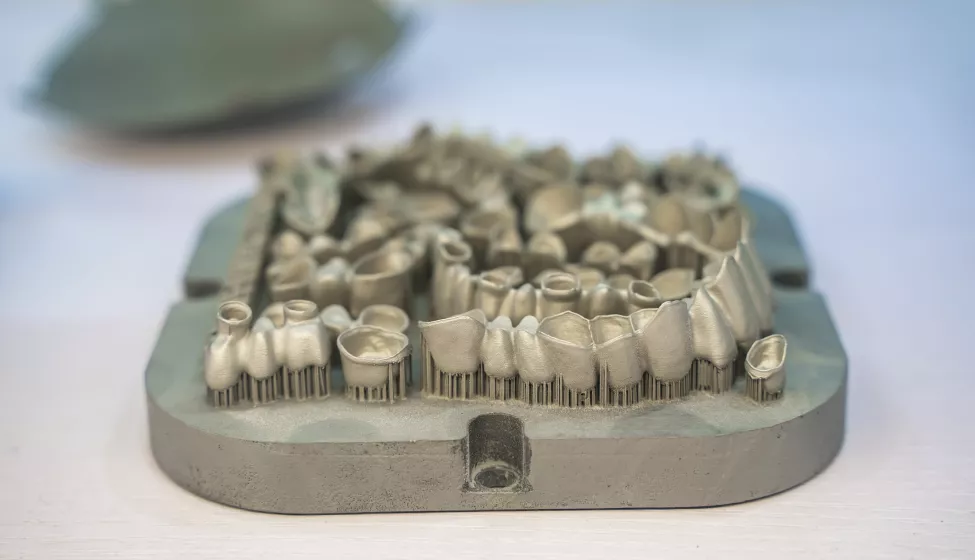

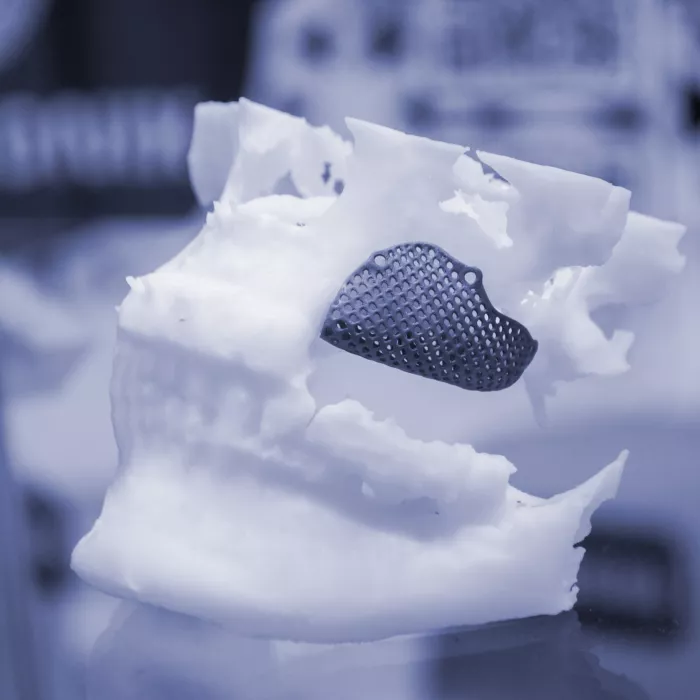

Innovation in materials chemistry and engineering has led to growing interest among medical industry stakeholders in 3D-printed metallic medical devices for a wide assortment of applications, including dental, orthopedic, cardiovascular, and neurological implants. Metallic devices manufactured through 3D printing methods, which leverage 3D model data, selective laser melting (SLM) of metals and alloys, and a layer-by-layer construction process, offer potential patient and application customization and performance advantages over conventional manufacturing processes — including machining, casting, and extrusion — and a host of new challenges in terms of safety and regulatory compliance.

In their article "3D-Printed Metallic Medical Devices: Increasing Interest from Medical Device Manufacturers, Opportunities & Challenges," cited in "A Detour Through Materials Science, Followed By A Climb Up A Rule 702 Hill | Drug & Device Law" published on the Drug & Device Law blog, Exponent scientists Ming Tang, Ph.D., and Larry Eiselstein, Ph.D., P.E., explore the current state of 3D-printing technologies in medical applications and challenges for the healthcare industry related to material properties, biocompatibility, and product regulatory frameworks.

They begin by examining the advantages of 3D printing, such as the ability to create complex geometries and patient-specific designs that are difficult to achieve with traditional manufacturing methods and that carry the potential to enhance patient quality of life. In addition, the authors explore a number of specific challenges, including the need for thorough testing and validation of the mechanical properties of these devices, rigorous biocompatibility evaluations, and long-term performance evaluations.

The authors highlight innovative testing and validation opportunities for 3D-printed medical devices through the use of machine learning and note that further research and collaboration between material scientists, engineers, and regulatory bodies is essential to address the remaining challenges and support the safe and effective integration of 3D-printed metallic medical devices into clinical practice.

"3D-Printed Metallic Medical Devices: Increasing Interest from Medical Device Manufacturers, Opportunities & Challenges"

Read the full article here.

From the publication: "Have you ever imagined an implantable medical device, manufactured specifically for your needs and available exactly when you need it? What once sounded like science fiction is now becoming reality, thanks to the revolutionary technology of 3-dimensional (3D) printing."