December 14, 2023

As a new battery belt develops through licensed equipment and technology, factories can benefit from focusing on operational maturity

Battery manufacturing in North America is primed for takeoff.

Some estimates suggest North American battery manufacturing capacity could be 20 times greater by 2030 than it was in 2021. To help fuel that growth, the Biden administration recently announced $3.5 billion in funding to strengthen domestic battery manufacturing.

Currently, many U.S. facilities rely on imported equipment and technology licensing deals with industry leaders in Japan, Korea, and China. Though these key partnerships with established companies offer obvious advantages for the nascent national industry, it's important to remember that it's taken decades of trial, error, failure, and continuous improvement for the world's biggest brand names to get battery production right — and then make it better.

Bringing North America up to speed with the hands-on, hard-earned operational lessons of established battery manufacturers will require more than importing equipment and technology. Since the batteries planned to roll off production lines in the U.S. and Canada are largely intended for electric vehicles, rigorous, experienced battery factory audits can bring new operations critical best practices. As operators seek to assess quality, design, corrosion mechanisms, and operational environments for these high-voltage applications, battery factory audits that bring the lessons of Asia to North America can help new manufacturing facilities reach production goals quickly, safely, and sustainably.

Manufacturing knowledge not included — getting set up and supporting workers

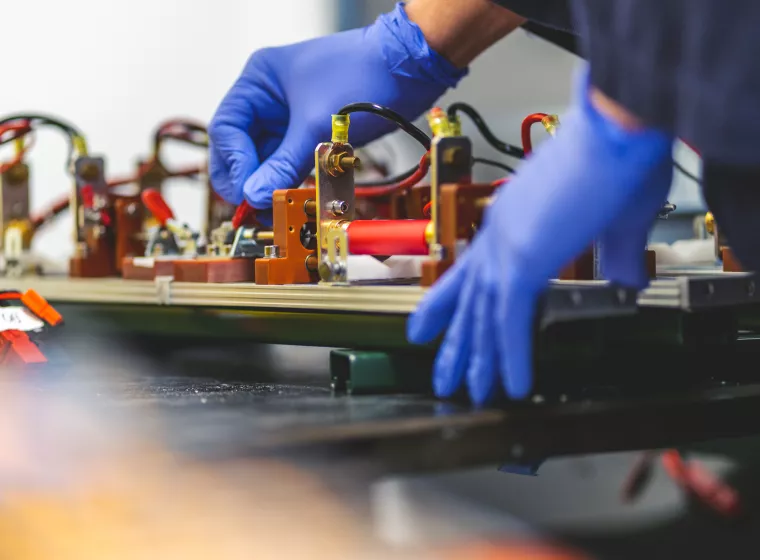

A typical battery plant functions as several micro-factories operating in parallel under one roof. Conducting this symphony of precise manufacturing — processing graphite materials to be coated onto foils to serve as anodes; slitting or stamping electrodes; assembling cells and bonding components in highly controlled dry and clean rooms to avoid contamination — requires carrying out fine-tuned, iterative, quality-control processes daily.

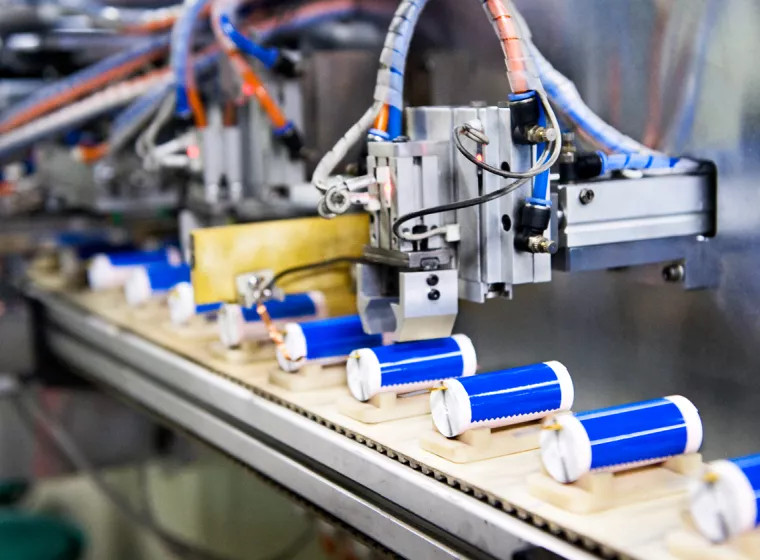

In practice, the ~30 planned North American battery factories are launching with licensed equipment from Asia, where over 1,000 battery plants are currently in operation. But differences in market maturity may become noticeable as U.S.-based battery plant operators move beyond initial training sessions to calibrate machinery and coax minute performance improvements from equipment with steep learning curves.

Manufacturing EV battery packs adds substantial complexity to the battery manufacturing process, as EV units must withstand large shock and vibrations as well as temperature fluctuations. Despite the widespread presence of EVs in the market, their battery production is not yet commoditized, with large variations across the industry. Some EV manufacturers are choosing larger stacked electrode configurations, while others are using cylindrical cells of increasing sizes, compounding their complexity.

That means most EV batteries are produced through custom designs that require specialized production lines for nearly all components. This creates additional opportunities for mistakes. It's not uncommon, for example, that the output of two parallel production lines following the exact same process will result in differences in quality and failure rates due to the experience and skill of the workers on the line.

Configuring and assembling imported equipment can be challenging, with licensing contracts typically offering limited setup support. Shipping electrode material for assembly in the U.S. creates additional failure modes such as contamination and degradation related to the shipping and handling processes. In the first phase of scaling their startup operations, battery plant operators will want to consider:

- Carefully inspecting and performing component- and site-acceptance testing of shipped parts.

- Expanding knowledge transfer with consistency, such as through detailed standard operating procedure documentation and performing necessary design of experiment processes to determine appropriate manufacturing techniques and controls to produce quality battery cell electrodes, battery cells, and assembled battery packs.

- Building in contingencies for manual inspection and operating processes between automated processes to help ensure product quality while automated processes are being optimized.

- Prioritizing worker awareness of the importance of specifications and inspections so that people are empowered to observe abnormalities and take initiative in improving processes.

For new battery factories, one limiting factor on quality and capacity may be plant arrangement and layout, as the configuration of equipment plays a pivotal role in controlling contamination sources and airflow that can taint production processes.

Audits to improve facility layout and boost automated manufacturing

Battery factory audits can also play a role in facility design. For new battery factories, one limiting factor on quality and capacity may be plant arrangement and layout, as the configuration of equipment plays a pivotal role in controlling contamination sources and airflow that can taint production processes.

Planning the right layout of a battery factory can be supported by:

- Finding appropriate environmental monitoring probe locations based on variations in temperature and humidity at different locations in a facility; air flow direction; worker and machine density; and storage locations.

- Sufficient separation between the anode and cathode production rooms and proper control of air handling and the manufacturing environment to minimize cross-contamination.

- Use of digital twins to simulate where various arrangements of conveyors, lines, pipes, beams can be configured and model how workers are anticipated to move and interact with the equipment.

- For manufacturers operating at a higher level of automation, similar simulations can yield production line designs with high throughput and automated manufacturing tasks.

Assessing quality, safety, and design in battery production

As completed batteries roll off the production lines of new battery factories, audits and assessments can also help accurately evaluate the operational environment and identify risks and mitigation steps. Elements of focus can include:

- Evaluating incoming materials inspection protocols, practices, specifications, and records to understand whether raw materials are being properly screened.

- Comparing raw materials handling, storage, and inventory controls to industry best practices to help minimize the risk of material contamination or degradation.

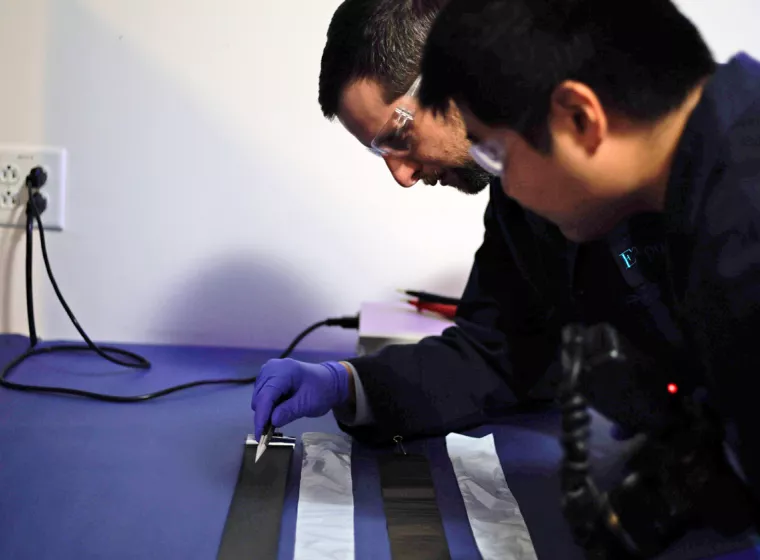

- Collecting and analyzing particulate contamination samples along the production line to identify any weakness in particle and contamination control.

- Identifying process optimization and improvement opportunities through experienced auditors who are familiar with industry best practices and common pitfalls.

- Evaluating the level of manufacturing expertise of management, R&D department, line operators, and quality control personnel. Identifying gaps between design and production specifications and actual production practices.

- Analyzing manufacturing conditions with respect to occupational health and safety as well as environmental impacts.

- Verifying proper and optimized operation of equipment to reduce the risk for contamination, damaged components or materials and improper quality control measurements.

- Evaluating implementation of statistical process control to help ensure such tools are being utilized appropriately to best control manufacturing processes.

North American factories risk repeating the pitfalls of newly launched operations as they kickstart serial production lines with daunting quality control operations.

Battery plant audits bring peace of mind and best practices to emerging factories

As large-scale battery manufacturing and assembly stands poised to become a competitive North American industry, factory audits can play a critical role in calibrating and sustaining the complex equipment used to manufacture battery cells and packs.

While the partnered manufacturing strategy has proven successful for EV battery manufacturers in Asia, North American factories risk repeating the pitfalls of newly launched operations as they kickstart serial production lines with daunting quality control operations. As North American battery manufacturers take up the production challenge of producing battery components with imported and licensed equipment, they can leverage cross-industry experience and audits to develop best practices and quality control for products that require sustained vigilance over the most minute manufacturing details.

What Can We Help You Solve?

Exponent offers multidisciplinary battery manufacturing and factory auditing services — including cell and pack testing, design and construction evaluations, and line quality assessments — to empower innovative, reliable battery product journeys. We support factory audits from incoming quality control (IQC) to outgoing quality control (OQC) and every step in between.

Insights