December 13, 2023

Biden administration restricts China and other countries from supplying battery components and materials for electric vehicles to receive tax credits

As the world leader in the production of electric vehicles and the materials powering them, China dominates the global EV market, producing about two-thirds of the world's EV battery cells. However, new rules issued by the Biden administration through the Internal Revenue Service and the Department of Energy are designed to expand the U.S.'s role in EV production while limiting the use of batteries and components from China and other "foreign entities of concern" (FEOCs).

FEOCs include companies based in China, Russia, North Korea, or Iran or companies in which the government of China, Russia, North Korea, or Iran holds "25% or more of an entity's board seats, voting rights, or equity interest." For consumers, this means EVs containing battery materials and components made by a FEOC will be ineligible for the 2022 Inflation Reduction Act 30D Clean Vehicle $7,500 tax credit, pressuring OEMs to meet the new criteria to remain competitive among buyers within just a few months.

New rules restrict eligibility for electric vehicle tax credits

Under the new rules, eligibility for the full EV tax credit means "vehicles placed in service beginning in 2024 must not have batteries containing battery components manufactured or assembled by a FEOC. In addition, vehicles placed in service beginning in 2025 must have not [sic] batteries containing applicable critical minerals extracted, processed, or recycled by a FEOC."

The new regulations expand on provisions in the 2022 Inflation Reduction Act mandating that, to be eligible for the tax credit, EVs must be "assembled in North America," with most of their battery components and battery minerals produced in North America and "with 40% of the critical minerals used to create a vehicle's battery to be extracted or processed in the United States, or a country that has a U.S. free trade deal."

New challenges for U.S. electric vehicle supply chain

While the new requirements are designed to create a U.S. supply chain for EVs, automakers will need to find alternative sources of EV battery materials and components. Other possible impacts could include a decrease in consumer EV purchases as buyers find it harder to locate one that qualifies for the tax credit. Consumers may choose to lease instead of purchasing, since the tax credit applies to leased EVs, but the new regulations limiting battery components and materials from China and FEOCs do not.

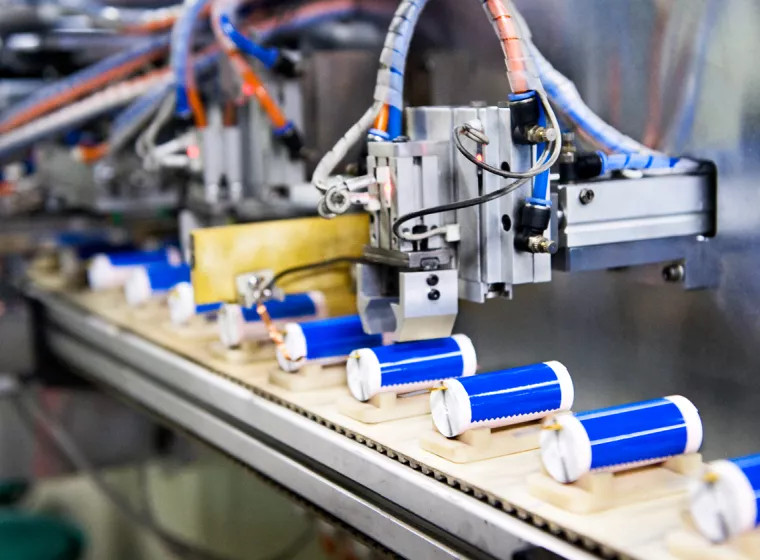

The new rules also pressure the growing number of battery factories under development in North America to scale more quickly to meet consumer demand. While production has been ramping up domestically, production capacity is not nearly sufficient to meet the predicted demand. Building the know-how and infrastructure to support domestic battery production is not trivial, and the U.S. is far behind countries in Asia that have been producing such batteries for decades. This will not only create supply chain challenges but also quality issues while U.S. manufacturers try to develop capabilities already in place in Asia. Presently many manufacturers are working to leverage Chinese partners to accelerate this process, but such regulations will inhibit these collaborations, and Chinese partners will likely receive pressure to avoid knowledge transfer.

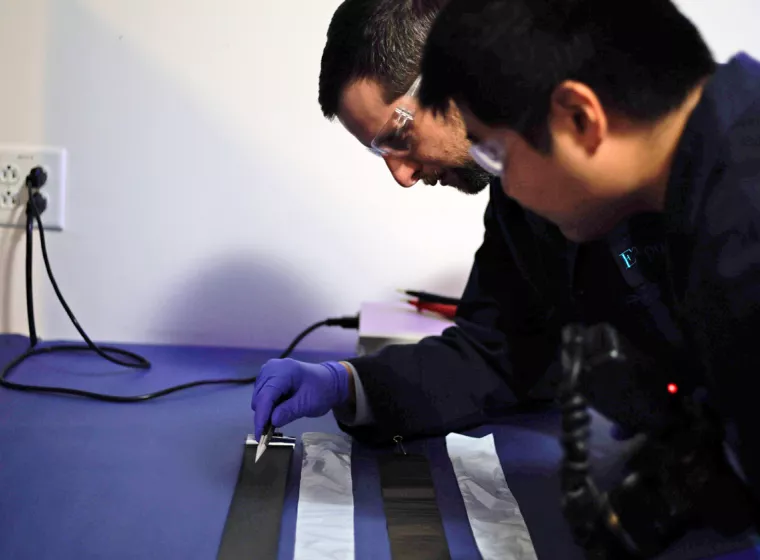

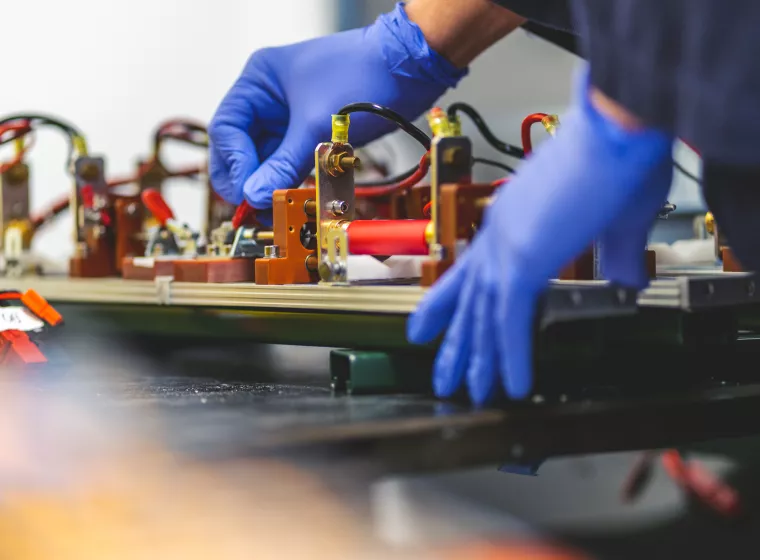

In adjusting their supply chains to ensure buyers are eligible for tax credits, EV manufacturers will need to carefully track battery components throughout the supply chain. Stakeholders will also benefit from battery design and manufacturing quality assessments as well as hands-on technical evaluations of manufacturing capabilities of battery manufacturers to better assess and optimize battery safety and performance, especially at lower volume custom production or when ramping up production in higher volumes.

What Can We Help You Solve?

Whether addressing a design component issue, conducting a failure analysis investigation, or tracing quality concerns across complex supply chains, Exponent offers multidisciplinary electric vehicle battery expertise. We have the resources and capabilities to work on-site or remotely with suppliers and manufacturers to assess all aspects of battery sourcing and performance.