Go Beyond Standard Tests and Protocols

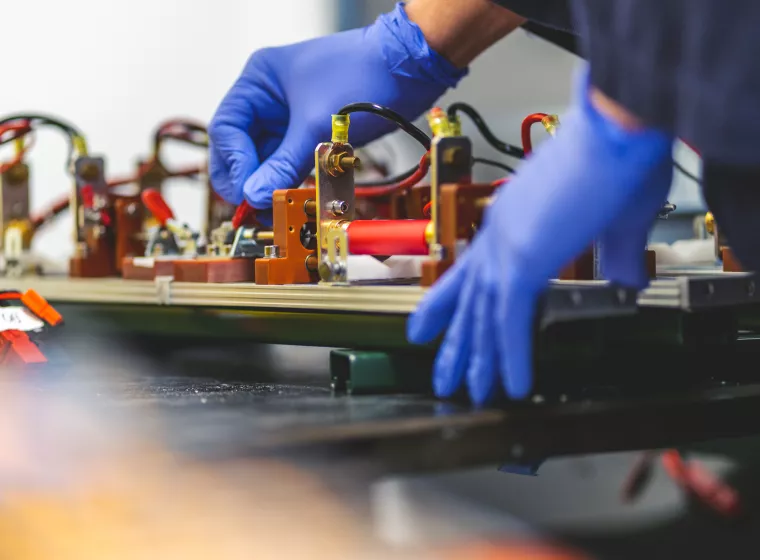

Count on Exponent for developing custom tests or test protocols to help you understand real-world conditions that aren't captured by standard tests. We leverage our diverse pool of expertise and rapid prototyping capabilities to quickly design and construct custom fixtures and instrumentation.

The broad range of test equipment and facilities that we have — both and Menlo Park and our labs around the world — can be leveraged to provide reliable, real-world validation data.

Exponent uses modeling and simulation to assist in design and failure analysis by evaluating the effects of loads on systems or products. Our interdisciplinary teams apply integrated capabilities to a breadth of scientific and engineering issues. Client projects range from medical devices to satellites to downhole tools for the oil and gas industry.

Exponent utilizes the most advanced software available for finite element analysis (Simulia Abaqus, ANSYS, and LS-Dyna) and fracture mechanics (Franc3D), and maintains a high performance computing cluster for executing simulations. We can tackle any modeling problem, no matter the size of the assembly or the complexity of the materials involved.

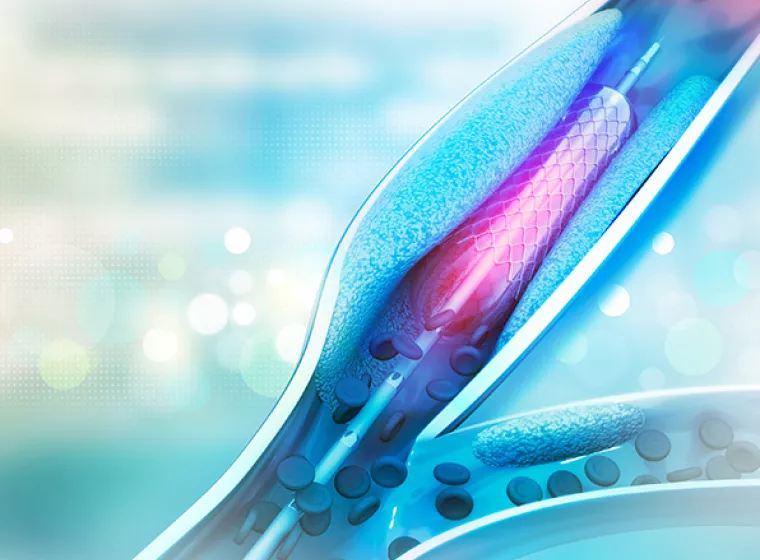

Biomedical Testing

Exponent's biomedical engineering laboratories in Menlo Park (in addition to our Philadelphia and Natick, MA labs) are accredited to ISO 17025 by A2LA for evaluating medical materials and medical devices. Some of the core services offered include:

Retrieval analysis to meet total product life cycle requirements

Wear and fatigue of orthopedic, spinal and cardiovascular devices

Biomaterials testing to meet supply chain requirements

Ex-vivo tissue mechanical testing and imaging

Accelerated aging, degradation and shelf-life testing

![Mechanical Lab [ME]](/sites/default/files/styles/fifty_media_large/public/media/images/GettyImages-1131116310.jpg.webp?itok=C0veqGD7)

Mechanical Modeling and Simluation

The mechanical lab team can tackle any modeling problem, no matter the size of the assembly or the complexity of the materials involved. Our facilities enable our team to obtain experimental results to supplement and validate our analytical models. Services include:

- Finite element analysis

- Fracture and fatigue analysis

- Vibration and rotating equipment evaluation

- Material constitutive modeling, testing, and evaluation

- Coupled structural, thermal, and fluid dynamics analysis

- Fluid/structure interaction analysis

Machine Shop

Our machine shop facilities and equipment provide capabilities — from machining to structural welding and cutting — for the rapid fabrication of prototype components for products including medical devices, electronics, and more.

Analytical Chemistry Laboratory

This lab is recognized as an ISO 17025 accredited laboratory (A2LA Certificate 2561.03). As applicable, the laboratory testing services are compliant with 21 CFR Part 58, U.S. FDA Good Laboratory Practices (GLP), and the laboratory holds a DEA registration for Schedules I — V.

Chromatographic Methods

Gas chromatography-mass spectrometry (GC/MS, TD-GC/MS, both liquid and vapor injection modes)

Ultra-high-performance liquid chromatography-QTOF mass spectrometry (UHPLC/MS, with tandem LC/MS/MS and photodiode array (PDA) detection capabilities)

Gel permeation chromatography (GPC) with refractive index (RI) and light scattering detectors (GPC-MALS)

Spectroscopy

Fourier-transform infrared (FTIR — transmission and ATR)

UV/Vis Spectrophotometer

Access to Raman and other spectroscopic instrumentation

Microscopy

Optical microscopy

Optical profilometry

Scanning electron microscopy (SEM)

Focused ion beam/transmission electron microscopy (FIB-TEM)

Non-destructive 3-D X-ray computed tomography (microCT)

Water content: Karl Fischer (KF) titration

Glove boxes for reactive or air-sensitive chemistry

Extractables and Leachables Testing per ISO 10993-18

Exponent routinely performs extractable and leachable protocols for a variety of materials in accordance with ISO 10993-18 and GLP support as required. Simulated-use, exaggerated, and exhaustive extractions can be conducted on devices or components to identify the quantities of the isolable material present. The analytical data produced can support toxicological risk assessments on components of concern by one of our in-house toxicologists or can be provided directly to the client for their own analysis.

Purity and Contamination Assessment

Our staff has extensive experience conducting purity assessments of pharmaceutical compounds in compliance with compendial methods (United States Pharmacopeia, USP) via UHPLC under GLP as required. We also have capabilities for developing and validating non-compendial and other custom methods for challenging matrices.

Since contamination can occur on surfaces and in products across many industries, we are prepared to assist clients when downstream contamination issues arise — whether at the formulation-level in products such as cosmetics, adhesives, and lubricants, or the system-level, at bonded interfaces, in assembled devices, on printed circuit boards, and elsewhere.

Method Validation

Our experts have assisted clients with quality assurance (QA/QC) test method validation to ensure that SOPs are properly developed and implemented. In addition to onsite manufacturing audits, we can assist in the verification and implementation of existing methods, either during technology transfer matters or other instances where analytical method adaptations are needed.

SCOPE OF ACCREDITATION TO ISO/IEC 17025:2017

Our Menlo Park laboratory successfully completed the A2LA Accreditation Program and is accredited to perform the following tests: