Our Shanghai facility includes labs for mechanical testing, failure recreation and product safety testing, battery testing, metrology, and chemical analysis.

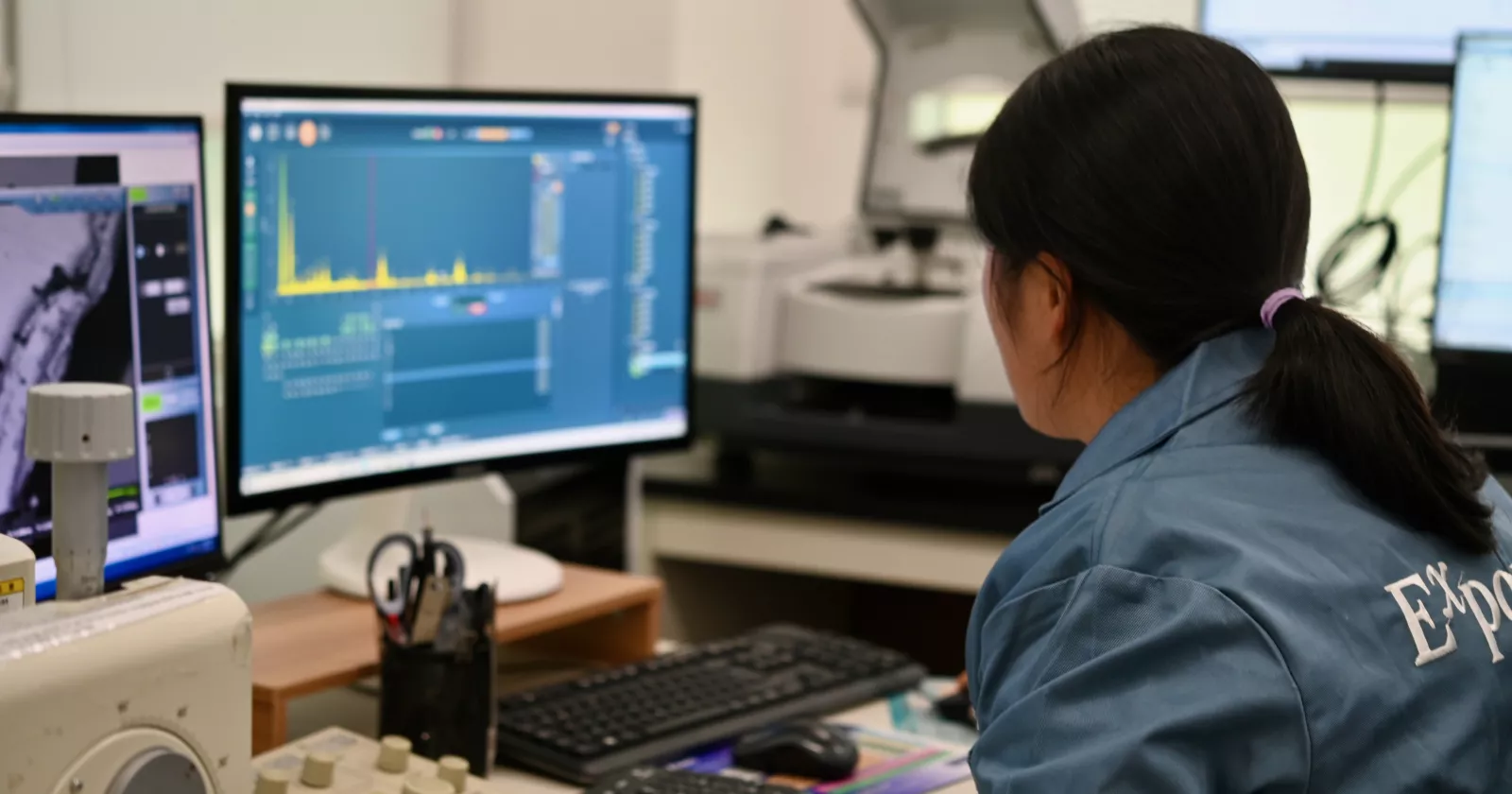

Chemical Analysis

Chemical analysis offers our clients the characterization and property evaluation of a variety of organic and inorganic based materials. As one of the essential steps in uncovering the failure root cause of a product, we evaluate materials such as small molecule chemicals, polymeric materials, and composite materials applied in sophisticated product systems.

Our Shanghai lab provides a wide array of capability in chemical analysis utilizing techniques including but not limited to microscopy, spectroscopy, chromatography — and as deep as sub-nano scale analysis:

Wet chemistry lab/hood

FTIR with both diamond and ZnSe crystal detectors

Micro-FTIR (reflection, transmission, and ATR mode)

AFM-IR

Raman spectroscopy

Confocal laser scanning microscopy (CLSM)

Cryo-microtome

X-ray photoelectron spectroscopy (XPS)

Gas chromatography — mass spectrometry (GC-MS)

Ion chromatography (IC)

UV-Vis-NIR spectrometer

UV aging system

Thermal analysis (DSC, TGA, DMA)

Nuclear magnetic resonance (NMR) spectroscopy

Inductively coupled plasma — mass spectroscopy (ICP-MS)

Mechanical Lab

The Shanghai mechanical lab allows our multidisciplinary teams to provide you with objective insights into your mechanical challenges. Our team can help you identify and resolve critical issues and flaws during the product life cycle including design, manufacture, testing, and end-use with the following services:

- Standardized testing to characterize a variety of mechanical properties at raw material, component, module, and system levels.

- Custom testing to analyze products under simulated end-use conditions, accelerated aging, and foreseeable misuse.

- Custom testing for applications requiring multi-signal monitor, gram-force/micron-displacement resolution, or specialized fixtures/loading conditions.

- Failure analysis and root cause validation with failure recreation testing.

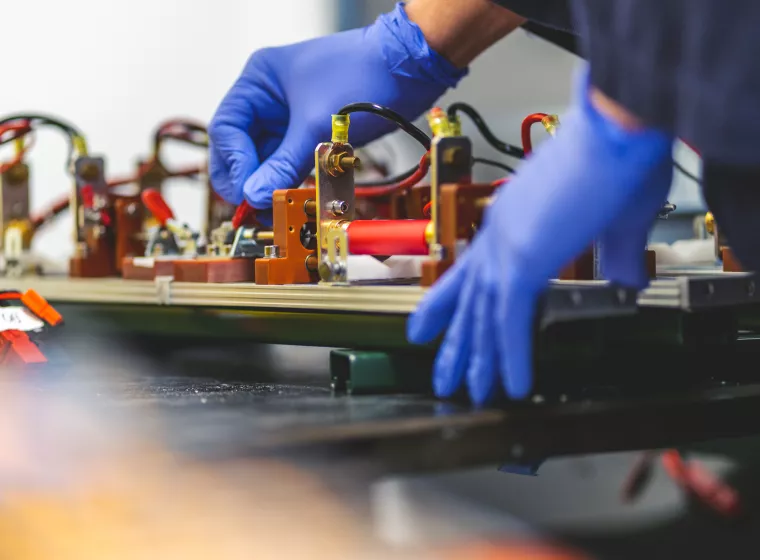

Failure Recreation and Product Safety Testing

Product safety testing at Shanghai offers a cross-discipline approach to identify hazards and evaluate risk associated with the product usage in a foreseeable manner.

Based on failure analysis experience of similar product and general risk assessment, our team of electrical engineers, battery engineers, mechanical engineers, and material scientists work together to develop customized testing to address specific safety issues that may affect the characteristics of your product.

Our lab is equipped with vents and explosion chambers to safely test your products in a variant of stress conditions. Some of the methodologies used include:

- Design review and risk assessment

- Fault injection testing

- Propagating circuit board failure evaluation

- Bench mark comparative assessment

- Gap analysis

- Thermal camera with micro lens

- 4K video camera

- Multi-channel data acquisition system

- X-ray/CT

Battery Lab

Battery-related services at Exponent Shanghai include a wide variety of categories. With our experienced engineers, we offer customized services and can help you to determine the cause of battery related product failures, identify potential safety risks in the manufacturing process, verify the quality of the batteries, and analyze the material used in the batteries.

Some of the methods used includes:

- CT/X-ray analysis

- Electrochemical testing at different temperature

- Battery tear down at different state-of-charge

- Battery material analysis with tools such as SEM, EDS, XPS, ICP-OES, and FTIR

- Battery and battery pack manufacturer on-site auditing

- Battery reliability testing

- Thermal failure analysis

X-ray and CT Lab

Our lab offers both in-house CT and a variety of external CT resources, giving us the capability to provide high-quality CT analysis on your component level samples with sub-micron resolution — as well as large samples including laptops, electric scooters, displays, battery packs, and more — without the need for disassembly and downsizing. CT scanning is a critical part of non-destructive analysis that is used to support our failure analysis investigations, product safety/product quality assessments, intellectual property investigations, and product liability support.

Exponent Labs and Facilities

Phoenix Test and Engineering Center

Offers state-of-the-art facilities to accommodate a wide range of testing and prototyping.

Menlo Park Laboratory

Develops custom tests and test protocols, in-house at our global headquarters.

Natick Laboratory

Studies everything from how batteries corrode in phones to how medical devices corrode in humans.

Philadelphia Laboratory

Test and evaluate biomedical engineering solutions in-house and through our network of third-party labs.

Seattle Materials Testing Laboratory

Provides top failure investigation and litigation support expertise.

Bowie Fire Engineering Laboratory

Helps your products, facilities, and systems pass tough fire and explosion standards.

London Laboratory

Assists with failure analysis, quality assessment, and product development in the UK and EU.

Hong Kong Laboratory

Brings extensive experience helping global manufacturers optimize products and processes.

Shanghai Laboratory

Works with global clients to support your teams in all phases of the new product integration cycle.