Evaluate medical implant corrosion performance under a range of conditions.

In vitro corrosion testing of medical devices and implants such as stents, clips, valves, dental implants, and joint replacement components can be performed to understand their electrochemical behavior and the release of associated degradation products during their service life.

In vitro tests assess corrosion and performance in vivo conditions.

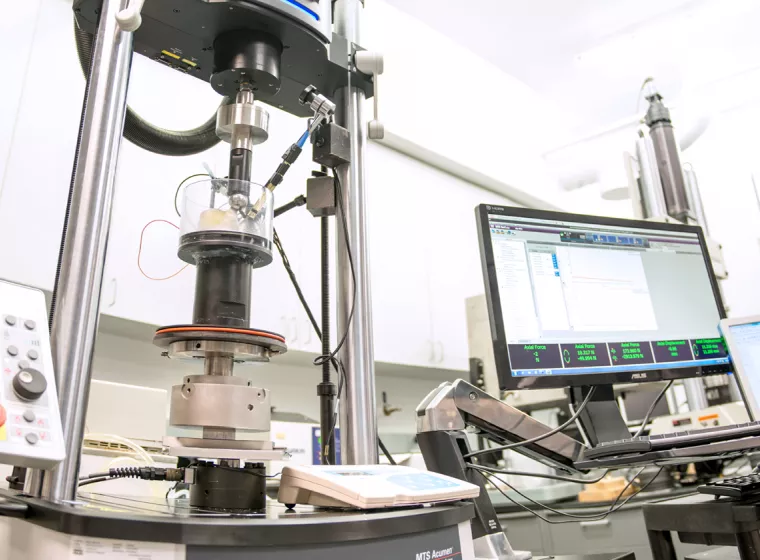

Exponent performs in vitro corrosion tests on medical devices to assess their corrosion performance under simulated in vivo conditions. Exponent regularly performs several different corrosion test methods to evaluate the short- and long-term corrosion potential, metal ion release, and breakdown and repassivation potentials of a variety of implantable medical devices in a wide range of shapes and sizes. Exponent also has extensive experience evaluating corrosion in retrieved medical devices.

Customized tests based on standardized techniques.

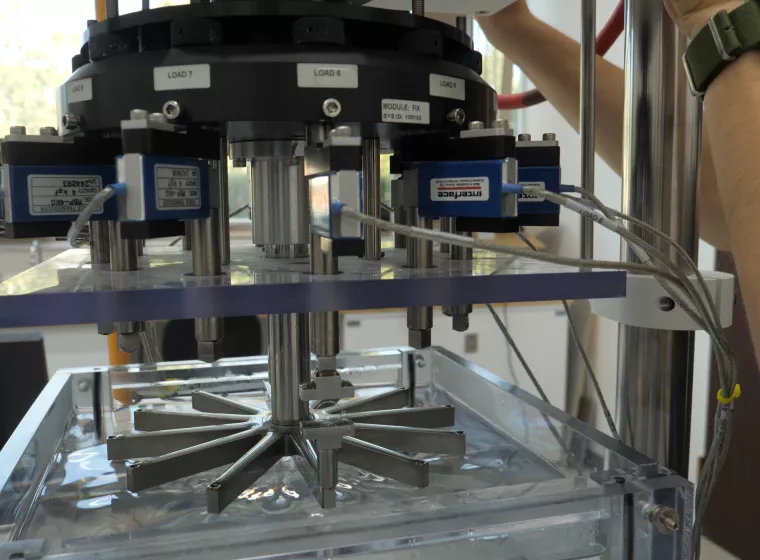

Our implant corrosion tests are performed using ASTM Standards F2129, F3044, F3306, F1875, and G71 and ISO Standard 16429 as guides, and we also design customized tests based on standardized techniques to evaluate unique device designs and geometries. We can evaluate electrochemical characteristics, including resistance to different types of corrosion, for various alloys used in medical devices.

Characterization of device materials and assessment of corrosion damage.

We have also helped several medical device manufacturers characterize fretting and corrosion damage in retrieved implants using physical measurements of total joint replacement components using ASTM F2979 and F3129 as guides.

State-of-the-art laboratories to characterize materials and chemical composition of devices.

Our labs have the capability to characterize implants and their materials to determine the amount, size distribution, and chemical composition of inclusions in their alloys and other features that can affect corrosion behavior using a variety of surface analytical techniques.

services

For 50+ years, we’ve thrived on solving unstructured problems that require bespoke solutions. Some of our services include:

• Evaluation of short- and long-term corrosion potential, metal ion release, breakdown, and repassivation potentials for pitting of implants

• Analysis of crevice, galvanic, or fretting corrosion

• Characterization of alloy microstructure

• Litigation support

• Evaluation of electrochemical characteristics using electrochemical impedance spectroscopy

• Open-circuit potential and breakdown potential analysis

• Examination of explanted devices

• Measurement and estimation of material loss from retrieved devices due to corrosion

• Evaluation of fretting and mechanically assisted corrosion in taper connections of modular implants

• Finite element analysis, failure analysis, and material verification

Our Capabilities Are Unparalleled

With expertise in over 90 disciplines and hundreds of capabilities, tools, and methodologies — we get to the root of even the most complex challenges and give you the objective answers you need.

Life Sciences Due Diligence

Due diligence technical consulting services to help verify the science and technology behind medical devices and related therapeutics.

Medical Device Evaluation

Sophisticated medical device evaluations for a vast array of applications.

Medical Device Design & Development Support

Crucial medical device design and development analyses to empower your decision-making.

Biomedical Expertise for Therapeutic Areas

Multidisciplinary insights for a range of therapeutic product development challenges.

Regulatory Compliance for Medical Products

Experienced regulatory support for medical devices, pharmaceuticals, and combination products.

Biomedical Engineering Laboratories

Expert biomedical laboratory services, delivering evidence-based answers for your most complex challenges.

Experts

Our global and comprehensive expertise across industries gives us a deep understanding of current challenges, best industry practices, and the implications of emerging technologies.

Group Vice President and Principal Engineer

Corporate Vice President, Office Director and Principal

![Fatigue & Corrosion [BES]](/sites/default/files/styles/hero_purple/public/media/images/GettyImages-1299847302.jpg.webp?itok=xzXUvdJu)