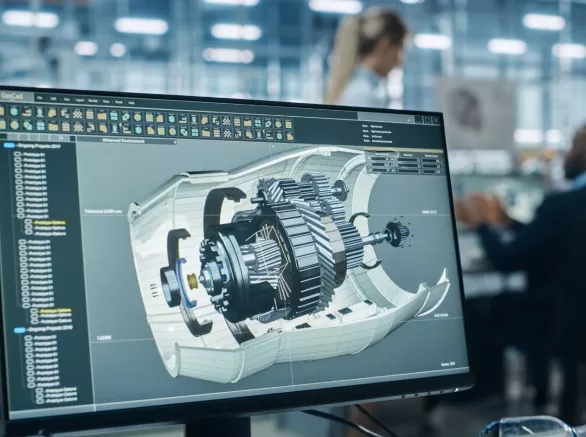

Can mechanical modeling and finite element simulations detect and help prevent design flaws and potential failures?

Exponent's mechanical engineers deliver advanced 3D mechanical modeling and finite element simulations to support design and failure analyses by evaluating the effects of mechanical and thermal loads on systems and products. Modeling solutions can be used to rapidly improve product design and introduce informative metrics that are difficult or impractical to measure experimentally. Our projects range in scale and scope, encompassing a variety of industry applications — from small medical stents to large tunnel boring machines and downhole tools for the oil and gas industry.

No matter the size of the assembly or the complexity of the materials involved, our team can tackle any mechanical modeling and simulation challenge. We use industry-preferred software for finite element analysis and fracture mechanics, and our laboratory facilities enable us to obtain experimental results to supplement and validate our finite element models, so we can provide you with real-world, experiment-backed insights.

Services

For 50+ years, we’ve thrived on solving unstructured problems that require bespoke solutions. Some of our services include:

• Computer-aided design (CAD)

• Finite element analysis (explicit and implicit stress analysis, heat transfer)

• Fracture and fatigue analysis

• Modal analysis

• Vibration and rotating equipment evaluation

• Material constitutive modeling, testing, and evaluation

• Coupled structural, thermal, and fluid dynamics analysis

• Fluid/structure interaction analysis

• Multiphysics simulations (e.g., structural mechanics, acoustic, electrostatic)

Experts

Our global and comprehensive expertise across industries gives us a deep understanding of current challenges, best industry practices, and the implications of emerging technologies.

![Mechanical Modeling & Simulation [ME]](/sites/default/files/styles/hero_purple/public/media/images/GettyImages-154962957.jpg.webp?itok=QlW1VMlD)

![Computational Modeling [TS]](/sites/default/files/styles/fifty_node/public/media/images/GettyImages-182174791.jpg.webp?itok=jTQjyv6E)