How does Exponent approach MRI safety and risk management using a multidisciplinary approach?

Magnetic resonance imaging (MRI) is a non-invasive and often lifesaving procedure that can also pose serious risks to patients with implanted medical devices. Many implanted devices contain metallic components that can interact with the magnetic fields of an MRI machine. These interactions can damage the device, create image artifacts, and harm the patient through device malfunction, unintended stimulation, heating, or magnetically induced force or torque.

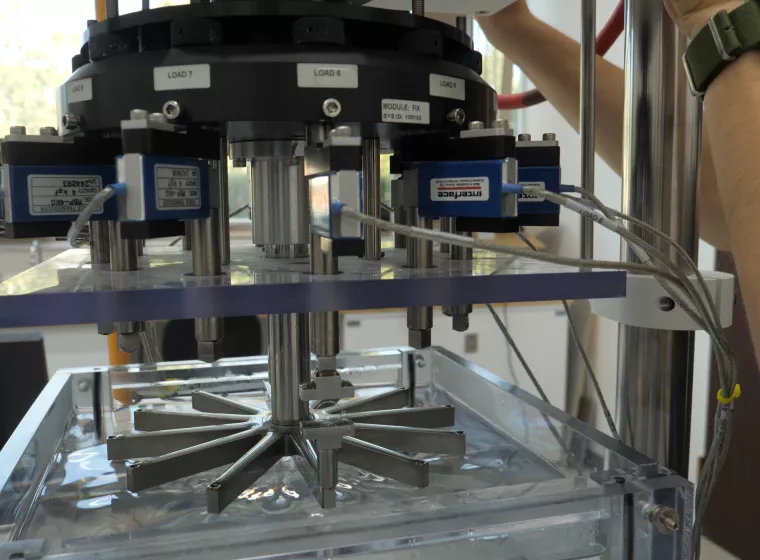

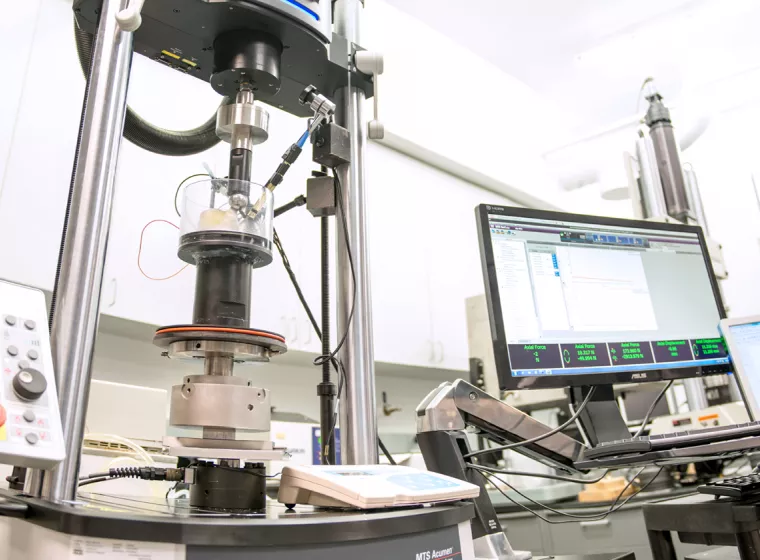

Exponent helps medical device manufacturers identify MRI compatibility hazards and optimize device designs for use in an MRI environment. Applying advanced computational modeling techniques for medical device testing, our MRI laboratory team evaluates worst-case scenarios that may occur while scanning a patient with an implantable device, and we assist clients in the feasibility and verification stages of product development through careful analysis of the collected data.

We also help medical device manufacturers meet regulatory labeling requirements through physical testing of the worst-case matrix for products. By leveraging our in-house benchtop radiofrequency and gradient coils, accredited by the American Association for Laboratory Accreditation, we provide analyses and labeling guidelines to help clients prepare regulatory submissions and formulate strategies for marketing devices evaluated for MRI safety.

We have the in-house capability, accredited to ISO 17025, to test in 1.5 T and 3 T MRI scanners in accordance with all applicable FDA guidance and ASTM International and ISO standards. We also have arrangements with regional research institutions to conduct studies at higher and lower field strengths, as needed. Our biomedical engineering experts are active members in standards committees related to MRI compatibility testing and routinely assist our clients in applying the standard methods to their specific products and indications.

services

For 50+ years, we’ve thrived on solving unstructured problems that require bespoke solutions. Some of our services include:

• Risk assessments and support of design changes to minimize risks

• MRI computational modeling and experimental testing on passive and active medical devices, including implantable cardiovascular, pulmonary, spinal, neurosurgical, and orthopedic products

• Testing of non-implantable medical devices designed for use in the MRI environment

• Human factors and usability analysis of labels and warnings

• Regulatory submission guidance regarding performance to standards associated with an MRI scanner

• Finite element analysis

• Failure analysis, including investigation of injuries in the MRI environment

• Comprehensive support throughout the medical device product lifecycle, including prototyping and preclinical assessment

We have conducted evaluations on a variety of medical devices.

Evaluation Experience

Neurointerventional devices (aneurysm clips and coils, hydrocephalus valves/shunts, neurostimulators)

Vascular implants (stents, valves, filters)

Interventional instruments (catheters, guidewires, endoscopes)

Orthopedic/spinal devices (joint prostheses, fracture fixation hardware, fusion, and deformity constructs)

Medical monitoring and support equipment (ventilators, drug pumps, continuous glucose monitors, monitoring equipment with carts and gas cylinders)

Electrophysiology devices (pacemakers, implantable cardioverter defibrillators)

Handheld surgical instruments

Implantable (cochlear) hearing devices