March 3, 2023

How EV manufacturers can harness emerging battery technologies to advance consumer safety goals

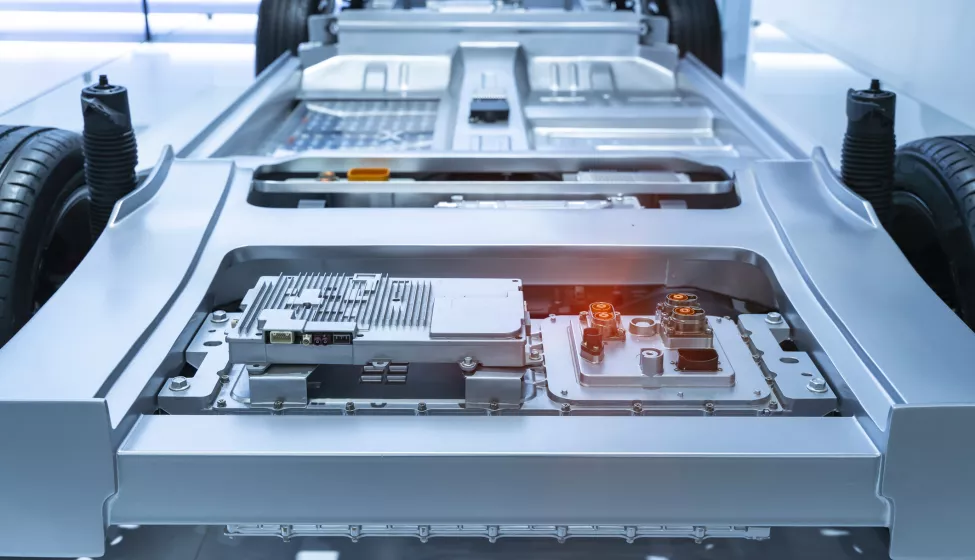

The global push toward a carbon-free future has sparked an electric vehicle (EV) revolution — and a rapid increase in lithium-ion (Li-ion) battery production to power millions of EVs. In parallel, technology is evolving to address consumer safety concerns and meet new regulatory standards governing EV battery production all around the world, including a transformative 5-minute warning system designed to protect drivers and emergency personnel.

The road ahead

For industry, the demand for Li-ion-powered EVs has reached an inflection point: more than 70 countries have pledged to achieve net-zero emissions in the coming decades, and some are planning to eliminate internal combustion engines at the same time. In the U.S., billions of dollars have been allocated to facilitate the nationwide transition to EVs, including infrastructure to support vehicle charging.

Because Li-ion batteries store large, concentrated amounts of energy and high voltages, related fires can present unique safety risks to emergency response teams like electric shock, propagating/delayed thermal runaway, and battery reignition.

As consumers negotiate this mass transition in what it means to drive a vehicle, ranging from daily questions (where to charge along the road) to differences in long-term maintenance (no more oil changes), EV manufacturers also have an opportunity to get ahead of the curve.

By harnessing emerging technologies focused on evolving EV battery pack safety, stakeholders can not only advance consumer safety goals but help ensure compliance with critical, fast-evolving regulatory oversight.

International regulatory milestones

One of the most significant steps toward a new EV battery safety requirement went into effect January 1, 2021, in China. As the world's leader in EV battery manufacturing, China mandated the implementation of an early battery failure detection system in all its EVs. This requirement spurred manufacturers to develop EV battery systems capable of providing a real-time notification warning the driver of an impending fire or explosion and allowing at least five minutes for occupants to escape the vehicle.

Later in 2021, the U.S. National Transportation Safety Board (NTSB) issued a recommendation to nearly two dozen vehicle manufacturers, calling on them to improve their emergency response guidelines to conform to existing international standards. Because Li-ion batteries store large, concentrated amounts of energy and high voltages, related fires can present unique safety risks to emergency response teams like electric shock, propagating/delayed thermal runaway, and battery reignition. As a result, the NTSB has urged manufacturers to inform first responders about how to overcome vehicle-specific challenges posed by these unique fires.

While the 5-minute rule is not in effect in the United States yet, both the U.S. and EU are likely headed in the same direction. A counterpoint to the China legislation has already been proposed by the U.S. Department of Transportation (DOT), and all countries are engaging in standards that extend beyond EV battery functionality as well. The EU, for instance, recently unveiled a "cradle-to-grave" blueprint regulating the entire battery lifecycle with a circular supply chain spanning production to recycling. These and other evolving standards are certain to impact stakeholders ranging from battery manufacturers to OEMs to consumers.

Trends, challenges & opportunities

The technical challenges of implementing these improvements, especially in providing an early warning detection system for battery failures, mitigating thermal runaway propagation, and helping protect passengers from hazardous scenarios, cannot be overstated. Meeting these core objectives — without substantially increasing the vehicle's cost or throttling its performance — has the EV industry at a challenging juncture.

While today's EV battery management systems often provide warnings in the case of abnormal readings of key parameters (e.g., temperature, cell voltage, and isolation resistance), regulatory trends can present opportunities for manufacturers to push the boundaries of what is currently possible and develop data-driven approaches to maximizing the safety and performance of battery packs.

Top-of-the-line occupant safety measures will inevitably function as market differentiators, similar to pricing, charging time, and vehicle range.

For instance, numerous sensors are under development to detect changes in gas composition and pressure to potentially identify and contain thermal runaway events by isolating the battery or preventing additional charging.

The collection of continuous battery state-of-health measurements is also leading to novel applications wherein how the battery is used changes based on its condition, leading to improvements in performance and longevity. For example, ongoing measurements of the battery, such as voltage and impedance, can be used to tune the maximum allowable charging rate of the battery as it ages. These settings could be unique to each vehicle to provide individual consumers with an optimal balance of performance, user experience, and safety.

Safer, more reliable EVs?

By employing large-scale, customized testing for EV batteries, manufacturers can understand a myriad of risk factors, including many that are difficult to predict in the design phase but become apparent during testing and field use. By identifying and assessing the unique risk factors of each system, EV manufacturers can position themselves to proactively address vulnerabilities through emerging technology solutions.

Manufacturers must also navigate the hurdle that while some solutions such as improved sensors may be easy to integrate with current EV battery pack designs, others, like solid-state batteries, are fundamentally different than current technologies and may require a redesign of the entire battery system.

These technologies could someday lead to EVs that are safer, more reliable, and more desirable for consumers, but they will demand different solutions for manufacturers in terms of reliability, mass production, and other design factors.

What's next for EV manufacturers?

Despite a growing number of automotive players and vehicles that use lithium-ion batteries, it's important to remember that technology is still evolving. As with any other consumer product, there will be a constant push for progress propelled by market forces — and increasing global regulations for safety.

For example, perhaps some manufacturers will explore how new technology can maintain — or even extend — the five-minute battery failure notification regulation. Could the next generation of batteries provide 10-minute warnings? Or can information collected from the battery pack be utilized to flag potential operational concerns and address them earlier in the battery's life, thus helping prevent safety issues from arising in the first place? Likewise, can EV manufacturers use battery information generated by a fleet of vehicles to proactively identify potential issues and remedy them through software updates that adjust how the EV battery is being used?

The potential answers to these questions point toward an exciting future. Given the massive global shift from internal-combustion transportation to EV production and deployment, it is imperative that companies developing and utilizing Li-ion battery technology quickly determine how to best meet and address fast-moving consumer demands and product safety regulatory frameworks.

Top-of-the-line occupant safety measures will inevitably function as market differentiators, similar to pricing, charging time, and vehicle range. Anticipating regulatory trends and consumer expectations will help manufacturers drive commercial success in an increasingly competitive business environment — while at the same time supporting the safety of consumers.

What Can We Help You Solve?

Exponent's multidisciplinary energy storage and battery technology consulting experts help ensure performance, reliability, and safety across all stages of the battery and energy storage product lifecycle.

Insights