June 28, 2024

SSBs hold high potential for EVs and electronics, but cell and system-level hurdles remain

Having long dominated the energy storage marketplace, lithium-ion (Li-ion) batteries are now facing a host of challengers at varying stages of development. Along with silicon-anode and sodium-ion battery chemistries, solid-state batteries (SSBs) are generating attention and garnering market share — spurred by their potential to offer longer lifespans, faster charging times, and increased energy storage capacity. Currently valued at $85 million, the market for SSBs is anticipated to increase nearly ten-fold to $963 million by the end of the decade.

In addition to increasing patent applications over the past several years, commercialization of SSB-enabled products is on the horizon. Hybrid SSBs that include a mix of solid and liquid electrolytes are already on the market, and products including fully solid varieties, such as Samsung's "battery of dream" smartphone and Toyota's ambitious 750-mile range SSB-powered electric vehicle, are anticipated in 2027. In the National Blueprint for Lithium Batteries 2021-2030, the U.S. government has also committed to developing SSB technologies as part of a holistic plan to advance domestic materials processing, battery manufacturing, and EV adoption — with a specific target to develop energy-dense SSBs for commercial EV applications. Several more global brands are planning to release their first generation of SSB EVs in the coming years, too.

To reach the scope and market saturation anticipated of SSBs, battery manufacturers, OEMs, and electronics companies will have to first contend with the unexpected risks and consequences that come with all emerging technologies. For SSBs, specific cell-level challenges heighten the demand for careful design strategies — some of which could add significant obstacles to SSB product development.

It's also important to note that system-level safety assessments are evolving in parallel with new SSB products and that the insights to be gained from real-world use are still years away. Likewise, safety standards specific to new SSB chemistries do not yet exist, meaning the onus is on stakeholders to conduct the rigorous, detailed assessments of both SSBs and their integrated systems to harness their promise at scale.

Advantages and obstacles on the path to market for SSBs

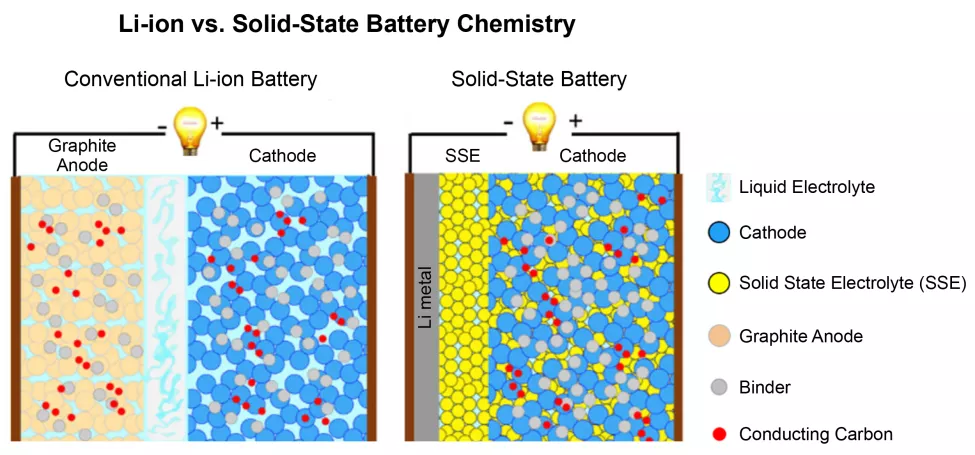

The drive to develop SSBs stems from several possible advantages they offer over conventional Li-ion batteries. By employing anodes with higher energy density, SSBs could potentially double the range of today's EVs. Proponents of solid-state technologies suggest the absence or reduction of flammable liquid electrolytes in most SSBs — replaced by an inorganic, non-flammable solid electrolyte to transport lithium ions between the anode and the cathode — may also increase their safety characteristics relative to conventional Li-ion battery technologies.

Due to the superior thermal stability of solid electrolytes, SSBs also have a higher threshold for material decomposition and subsequent thermal runaway (~200°C) compared to traditional liquid electrolyte-based batteries (~70°C). This means they could mitigate many of the fire risks of conventional Li-ion battery electrolytes that have drawn public scrutiny in recent years.

On the other hand, challenges across various aspects of SSB development present complex obstacles for stakeholders, including material selection, cell resistance, and system integration.

Material selection

SSBs enable the replacement of graphite (see fig. 1) with higher energy density materials to achieve performance benefits. Lithium metal is an option, but in conventional Li-ion batteries, its highly reactive nature often results in unstable lithium plating, dendrite formation, and separator damage, compromising overall safety by creating a risk of short circuiting in the cells. Silicon is another potential substitute for lithium metal as a negative electrode, but its application is limited by issues such as a ~300% volume increase upon lithiation (charging) and gradual degradation, similar to the common issues associated with liquid electrolytes. SSBs can potentially offer improved structural integrity and chemical stability to protect against dendrite formation and material degradation, but whether lithium metal or silicon can broadly serve this purpose is not yet clear. For stakeholders, selecting and testing materials on a case-by-case basis, considering the specific use of the intended product and its application, can support product development while cell technologies are still evolving.

Cell resistance

The cell resistance of any battery (its ability to carry a current) depends on the resistance of each component inside it, especially the interfacial contacts between electrodes and electrolyte. These contacts can become highly resistive in solid-to-solid interfaces, which can result in limited power applications, early aging, and faster failure rates for SSBs. Despite advancements in a new generation of solid electrolytes with higher performance, e.g., halide superionic conductors and sulfide-chloride conductors, their commercial use is also yet to be explored.

Lithium dendrites can also penetrate through brittle solid electrolytes and cause internal shorting, which rapidly converts stored energy into heat, posing a risk of lithium metal-induced fire. Thermodynamic models predict that the total heat release due to internal shorting of an SSB could be significantly higher than their liquid electrolyte counterparts, especially given the increased energy density goals of SSBs. This means that even with an overall strong safety profile, a fire incident for an SSB-enabled device or vehicle could be devastating in scale.

If SSBs are to displace Li-ion batteries in consumer electronics and EVs, they'll not only require best practices in advanced battery testing but thorough consideration of the design elements needed to support system-level integration.

System integration

Other challenges distinguishing the path to market for SSBs include a higher stack pressure (necessary to capture performance gains) and higher operating temperature (necessary to mitigate resistive interfaces). For potential EV applications, a higher operating temperature is critical for power and performance, as well as functional operation in cold environmental conditions. This demand on the operating temperature of SSB cells could create new requirements for thermal management systems, increasing the number of components and complexity of the pack alongside the overall weight and cost of the vehicle.

Maintaining sufficient quality in the interfacial contact of solid parts throughout the cycling life of an SSB is key, as is managing the stress applied to cell components. These cell-level particularities add to the complexity of manufacturing SSBs, as well as integrating them with products. For OEMs and other stakeholders, anticipating the demands of the high stack pressure and high operating temperature of SSBs for their use in EVs will be critical to safety. In collisions, battery pack enclosures can encounter major mechanical damage, leading to cell-level shorting, coolant leakage, and subsequent thermal runaway propagation to neighboring cells. Due to the high reactivity of lithium metal in the presence of moisture and air, any potential breach in the cells can lead to catastrophic thermal events.

An efficient flame retardation or management system in SSB-equipped EVs will be an important aspect of preventing cascading thermal propagation events and fires — but it may look very different compared to current systems designed to protect Li-ion-powered EVs, which may not be effective for SSBs. OEMs can benefit from assessing the most effective design strategies, including pack-level failure mode design, and carefully considering the battery configuration, materials, and associated cooling systems.

The path to SSB implementation

If SSBs are to displace Li-ion batteries in consumer electronics and EVs, they'll not only require best practices in advanced battery testing but thorough consideration of the design elements needed to support system-level integration. This can include detailed simulated failure scenarios to gain understanding of how SSBs are likely to perform under various damage conditions, ahead of their real-world use.

Current Li-ion and lithium metal battery safety standards do not differentiate between the physical state of the electrolyte, whether liquid or solid. As new standards specific to SSBs emerge — including those related to battery management system design, thermal management systems, and casing design — OEMs, electronics companies, and the battery manufacturers that supply them will play an instrumental role in helping pioneer their development and implementation.

Achieving this will entail in-depth characterization of SSBs for each individual application. Combining electrochemical techniques with calorimetric evaluation of their thermal runaway can be a starting point for designing and engineering safer SSB management. Risk assessments, abuse testing, vendor supply chain analysis, and other evaluative factors are also key aspects of bringing SSB innovation to market for companies to thoroughly understand the performance, safety, reliability, and risk profile of SSB-enabled products.

What Can We Help You Solve?

Exponent leverages over two decades of battery failure analysis and quality assessment to help improve performance and safety for consumer products, electronics, medical devices, and EVs. We provide customized testing solutions for solid-state battery technologies, and we've helped battery manufacturers and OEMs manage major recalls and review new designs.

Batteries & Energy Storage

Supercharge performance, reliability, and safety across all stages of the battery and energy storage product lifecycle.

Battery Failure Analysis & Investigation

Comprehensive battery failure analysis to determine the root causes of failures and identify opportunities for mitigation.

Battery Design Review, Quality & Safety Assessments

State-of-the-art battery design, performance, quality, and safety assessments to support manufacturers' requirements and industry standards.

Custom Battery Testing

Custom product safety, performance, and industry certification battery testing services.