December 17, 2024

This article first appeared in Sedgwick Brand Protection: State of the Nation 2024 Recall Index Report.

Addressing product safety challenges with growing intel on real-world EV performance

The global push toward a carbon-free future has sparked an electric vehicle (EV) revolution and a subsequent rapid increase in lithium-ion (Li-ion) battery production to power the millions of EVs on the road. For the automotive industry, the demand for Li-ion-powered EVs has reached an inflection point. More than 100 countries have pledged to achieve net-zero emissions in the coming decades, and some are planning to ban the sales of new internal combustion engines at the same time.

In the U.S., billions of dollars have been allocated to facilitate the nationwide transition to EVs, including infrastructure to support a national network of vehicle charging stations. Annual global EV sales are also growing steadily as underlying technologies mature, EV costs decrease, and new regulatory obligations loom.

As consumers continue to adopt EVs in greater numbers, manufacturers have an opportunity to proactively mitigate the unique potential safety risks. By harnessing emerging technologies to improve EV battery safety, stakeholders can not only advance consumer protection goals but also help ensure compliance with critical, quickly evolving regulatory requirements.

Product safety challenges for the EV industry

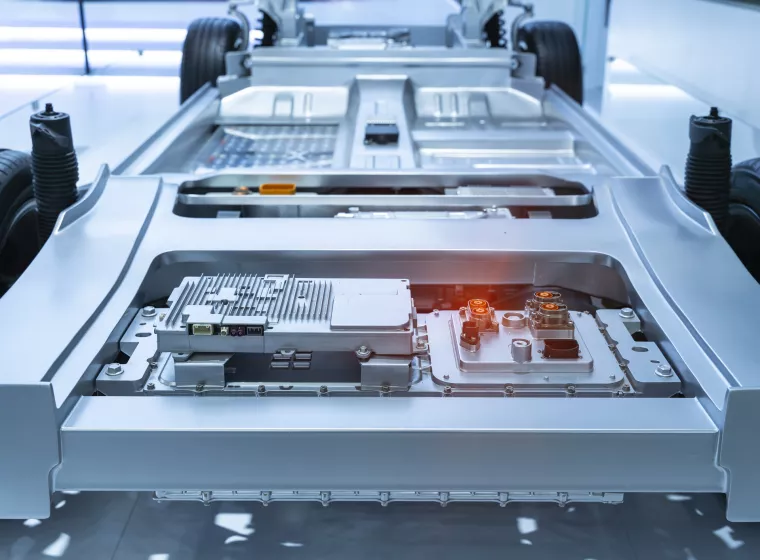

As EV technologies and regulations develop, the automotive industry is faced with numerous product safety challenges ranging from advanced driver assistance systems (ADAS) to crash safety for large-format battery systems. EVs present new challenges with respect to their weight and the interaction with the U.S. transportation infrastructure. Many EV batteries weigh more than the internal combustion engines they replace. Recent findings by road safety officials have shown that automotive guardrail barriers may be insufficient for heavier EVs at certain speeds.

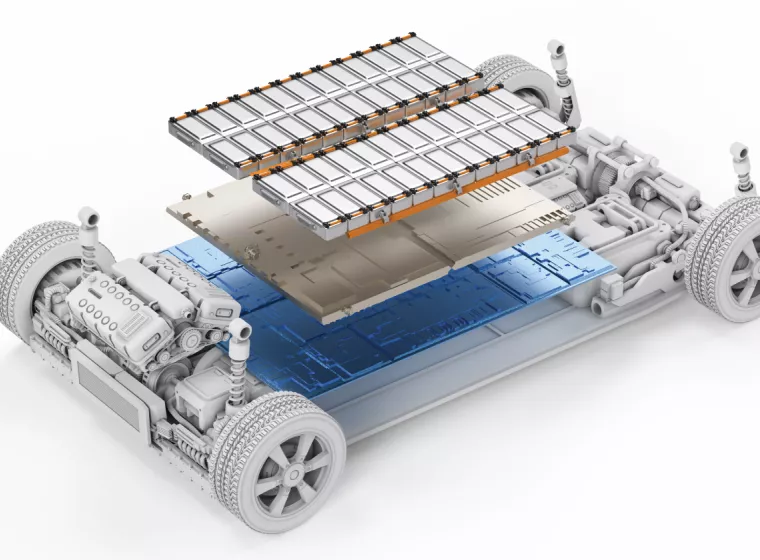

More broadly, many automakers are focused on how to manage the technical challenges related to large-format battery systems as more and more of these batteries are incorporated into vehicles. These concerns include implementing sophisticated improvements such as early warning detection systems that alert passengers to potential battery failures, ways to protect passengers from hazardous scenarios, and measures to mitigate thermal runaway propagation within the battery pack that can lead to battery fires.

Meeting these core objectives without substantially increasing the vehicle's cost or throttling its performance has put the EV industry at a critical juncture.

The role of data in the future of EVs

Anticipating regulatory trends and consumer expectations can help manufacturers drive commercial success in an increasingly competitive business environment while simultaneously supporting consumer safety. As EVs evolve, the use of data to drive the battery pack design, develop robust testing and validation programs, and implement sophisticated battery management programs will be critical to shaping the future of EVs.

While today's EV battery management systems often provide warnings for abnormal readings of key parameters (e.g., temperature, cell voltage, and isolation resistance), opportunities exist for manufacturers to develop advanced, data-driven approaches to maximize the safety and performance of battery packs. For instance, numerous sensors are under development that can detect changes in gas composition and pressure to potentially identify and contain thermal runaway events by isolating the battery and warning passengers or others nearby of a potential hazard.

Furthermore, the collection of continuous state-of-health measurements for batteries is also leading to novel applications where battery usage changes based on its condition. These adjustments lead to improvements in battery performance and longevity. Ongoing measurements of the battery, such as voltage and impedance, can be used to tune the maximum allowable charging rate of the battery as it ages. These settings could be unique to each vehicle to provide individual consumers with an optimal balance of performance, user experience, and safety. The adjusted control parameters can either be administered through on-board programs or through periodic software updates and may not even require action from the EV owner.

Continuous real-time monitoring and analysis of battery pack data such as charge and discharge characteristics, cell-balancing activity, thermal management operations, and fault diagnosis can identify predictive maintenance strategies, indicate the need to adjust operational conditions, or reveal opportunities to potentially lower the risk of an issue.

The changing recall landscape

Government agencies around the world have indicated that new regulations to advance EV safety are on the horizon. The U.S. and EU have announced their intent to require early battery failure detection systems in all future EVs and will also engage standards that extend beyond EV battery safety and functionality. For instance, the EU proposed a "cradle-to-grave" blueprint regulating the entire battery lifecycle with a circular supply chain that spans production to disposal and recycling. These and other evolving standards are certain to impact a range of stakeholders from battery manufacturers and OEMs to consumers.

Even EVs that are compliant with current standards can have unexpected issues arise which may require a recall or other reactive technical solution. Increasingly, data can help manufacturers respond more quickly and effectively to these issues.

Continuous monitoring

With the growing adoption of EVs, the data collected through the number of miles on the road can provide critical insights into charging and discharging behavior and trends over the lifetime of a vehicle. Continuous real-time monitoring and analysis of battery pack data such as charge and discharge characteristics, cell-balancing activity, thermal management operations, and fault diagnosis can identify predictive maintenance strategies, indicate the need to adjust operational conditions, or reveal opportunities to potentially lower the risk of an issue.

Defining recall size

Manufacturers who achieve data visibility across the battery and powertrain can also identify potential issues and/or scope recalls on a more granular level. This includes the ability to isolate the potentially affected production lot and trace the origin of defective components.

Deploying a software information architecture that fully leverages the data streams of EVs can enable vehicle-by-vehicle analysis during a warranty or recall investigation versus having to cast a wider net over a vehicle's lot or model. By assessing an individual vehicle's performance for degradation or failure markers, the number of affected vehicles in a recall can be minimized to only those exhibiting the relevant characteristics or behavior. In turn, this could substantially reduce the potential cost of a recall for EV manufacturers and improve customer outcomes.

What's next for EV manufacturers?

Despite the growing number of automotive players and EV models on the market, it is important to remember that the technology is still evolving. As with any other consumer product, there will be a constant push for progress propelled by market forces and increasing global safety regulations.

EV manufacturers will continue to evaluate new battery cell chemistries and technologies to reduce potential safety risks and improve the mileage range of EVs. Similarly, advanced data analytics can help better utilize information collected from the battery pack to flag potential operational concerns and address them earlier in the battery's life, thus helping prevent safety issues from arising in the first place.

Likewise, EV manufacturers may develop techniques to better harness information generated throughout a fleet of vehicles to proactively identify potential issues and solutions that wouldn't have been easily identifiable by analyzing a small subset of the vehicle population.

Beyond safety-related issues and recalls, EV manufacturers should also be prepared to address gaps between users' expectations and real-world performance. The Environmental Protection Agency range and the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) range used in the EU represent test results for an EV's driving range under specific test conditions. It is not uncommon for real-world driving results to differ from test conditions, resulting in different ranges between estimated and actual performance. An EV's true range depends on many variables such as throttle and/or braking tendencies, temperature, road conditions, etc.

The potential gap between the battery range or battery life advertised during purchase compared to what consumers actually achieve could lead to disputes, similar to what has occurred with consumer electronics. In the same vein, if battery pack performance is changed remotely by an automaker to preserve its lifespan or for safety or other reasons, the resulting reduction in mileage may also be perceived negatively by consumers. Striking the balance between optimizing performance, reliability, and safety — and attempting to match the marketed range estimates — will be crucial for automakers.

Manufacturers must also navigate the challenge that while some solutions such as improved sensors may be easy to integrate with current EV battery pack designs, new innovations such as solid-state batteries are fundamentally different than current technologies and may require a redesign of the entire battery system. These advances could someday lead to EVs that are safer, more reliable, and more desirable for consumers, but they will demand different solutions for manufacturers in terms of reliability, mass production, and other design factors.

Vehicle manufacturers will have to adapt to many changing regulations and expectations in a heavily regulated environment. The ultimate goal of protecting the environment and consumers is admirable, but the path there will be challenging.

What Can We Help You Solve?

Whether addressing a design issue, conducting a failure analysis, or tracing quality concerns across complex supply chains, Exponent offers multidisciplinary electric vehicle expertise. We work with suppliers, manufacturers, and operators to assess all aspects of battery sourcing and performance, regulations and funding opportunities, safety, and logistics.

Vehicle Engineering

Rigorous research on the safety and performance of all types of transport and cutting-edge technologies.

Emerging Vehicle Technology Development

Balance safety and performance while advancing innovative transportation technologies.

Component, System, and Vehicle Analysis & Testing

Cutting-edge automotive research, product evaluations, and real-world vehicle testing.

Battery Failure Analysis & Investigation

Comprehensive battery failure analysis to determine the root causes of failures and identify opportunities for mitigation.

Custom Battery Testing

Custom product safety, performance, and industry certification battery testing services.