THE CHALLENGE

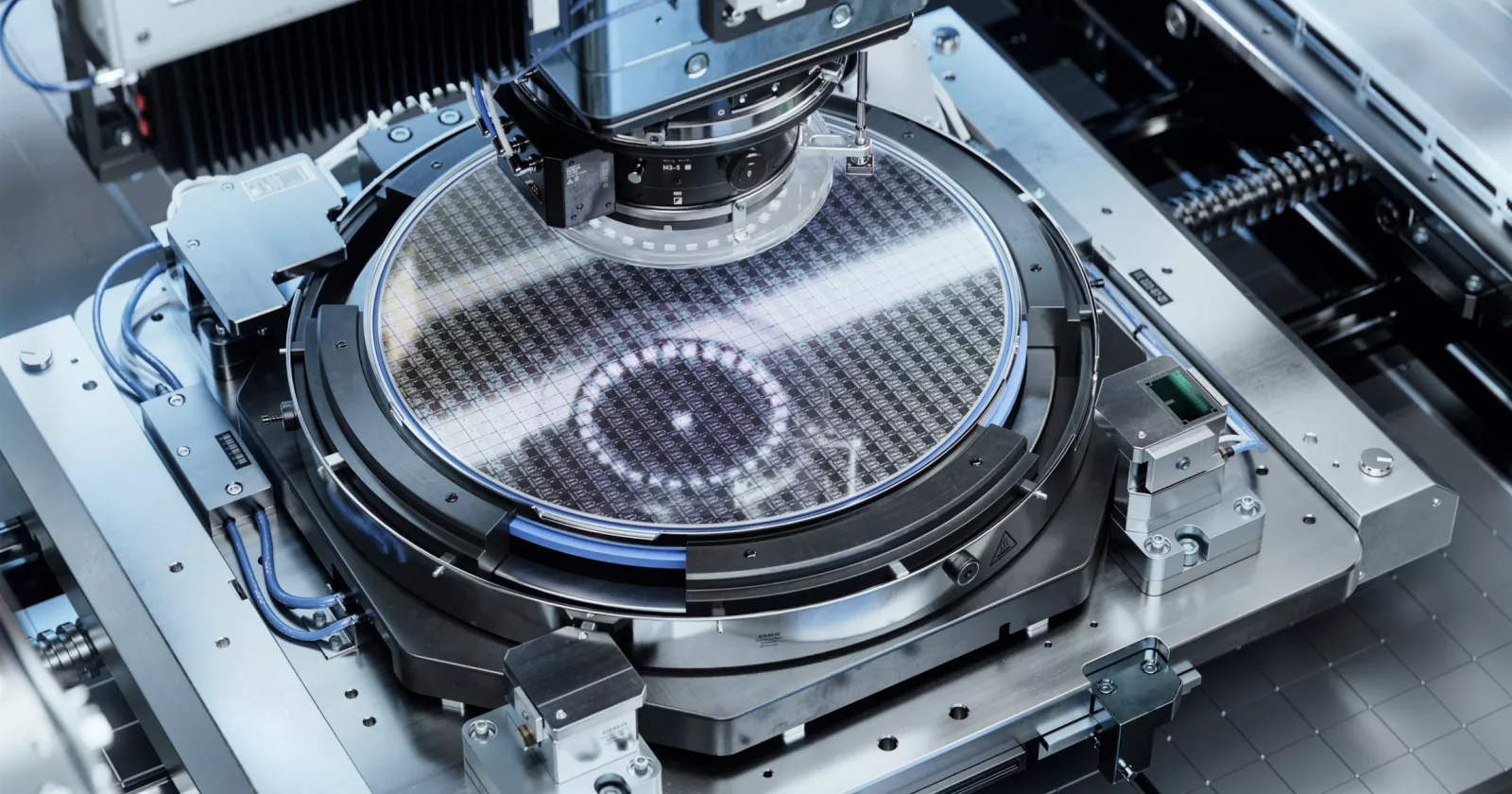

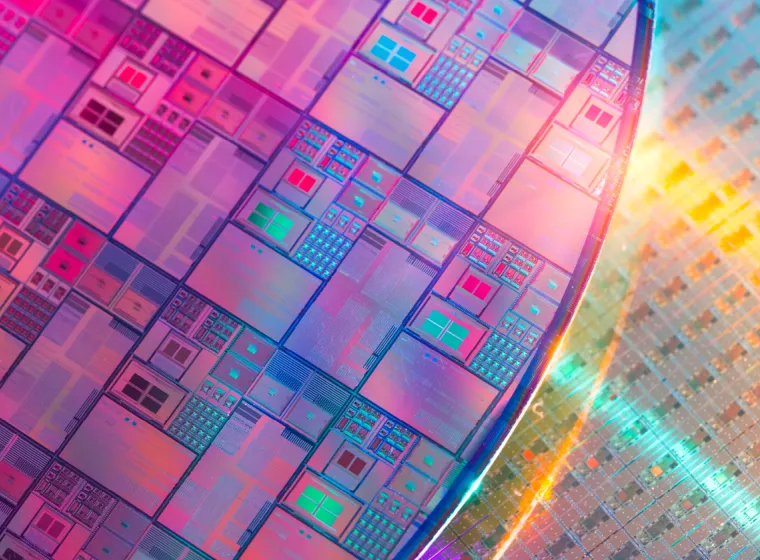

The electrostatic chuck is the foundation of many microchip manufacturing operations. It supports silicon wafers as they are processed to make microchips. A ceramic coating on the chuck protects it from the erosive, high-energy environments used to fabricate chips, and a durable coating can provide a competitive edge for chip manufacturers. Our client needed to develop a testing strategy that could determine the lifespan of their chuck coatings — and they turned to Exponent to make it happen in days, rather than months.

EXPONENT'S MULTIDISCIPLINARY SOLUTION

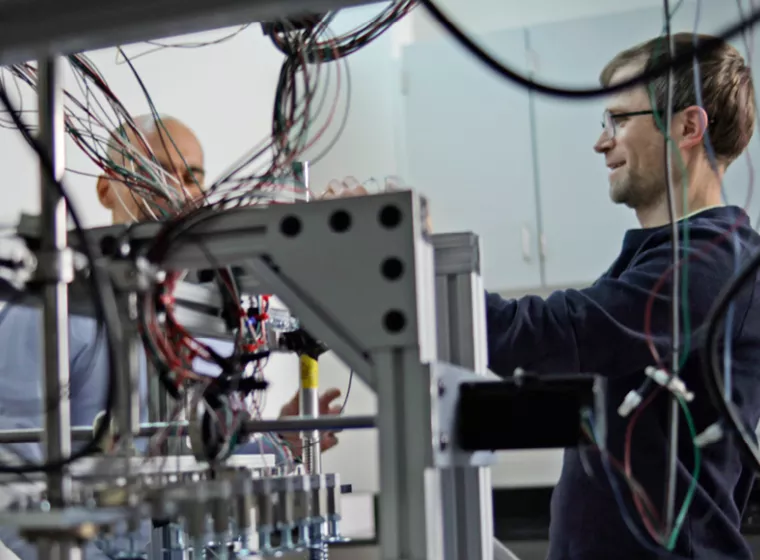

Exponent's team of multidisciplinary experts worked together to design a test fixture, re-create failure modes, and test physical samples. Engineers and scientists specializing in thermodynamics, vacuum systems, process control, optical profilometry, and fracture mechanics came together to create a streamlined test regiment for our client.

Our Impact

Exponent's novel test design accelerated the evaluation of new electrostatic chuck coatings from months to days. The insights provided by Exponent's custom testing protocol are allowing our client to rapidly improve their production designs through data-driven decision-making.

Our ability to develop both custom testing fixtures and associated protocols to conduct rapid testing of materials and equipment is supporting advancements in microchip manufacturing and helping to meet the ever-growing demand for microchip production and performance.

What Can We Help You Solve?

Exponent materials and corrosion experts can help you with materials wear assessment through every stage of the product lifecycle, from development to production to product improvement. Exponent can develop and conduct unique tests to simulate real-world conditions and wear for a wide variety of products and applications.

Metallurgical & Corrosion Engineering

Valuable insights for your most formidable metallurgical and corrosion engineering challenges.

Design Evaluation & Materials Selection

Quantifiable, evidence-based information for better materials selection and business decisions.

Electrical Materials & Circuit Packaging

Overcome challenges in electrical materials and packaging, such as semiconductor and dielectric materials.

Polymers & Chemistry

Multidisciplinary support for materials challenges for diverse clients and applications.

Materials, Metallurgy & Corrosion Engineering Capabilities

Assess corrosion risks and follow best practices in materials selection, operations, and corrosion control for metals.

Materials & Corrosion Expertise for Consumer Electronics

Expert materials and corrosion analyses for consumer electronics.