December 16, 2021

London's ban follows a number of battery-related fires involving e-scooters

Starting Monday, December 13, 2021, Transport for London (TfL) has banned e-scooters from all public transportation and transit facilities following a series of high-profile incidents involving battery-related fires. The ban extends to all privately owned e-scooters, even when folded and carried.

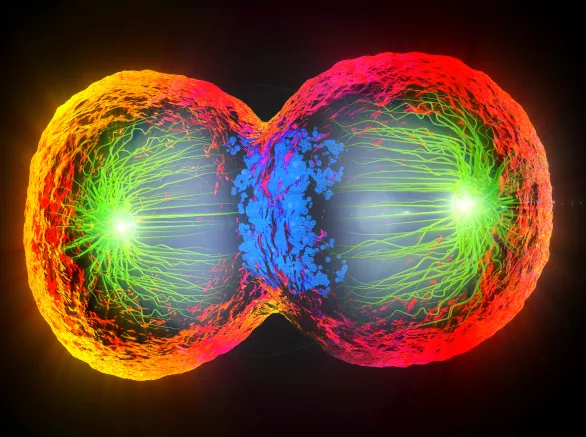

The size and capacity of the lithium-ion batteries used in e-scooters and other micromobility applications pose potential risks to users and the public, the dangers of which are naturally increased in enclosed spaces such as an underground tube station.

Notably, the ban does not include mobility scooters or foldable e-bikes because, as reported by The Guardian, the TfL said these products are "generally subject to better manufacturing standards and less of a fire risk."

Standards exist for some micromobility products, for example, EN 50604-1:2016 (secondary lithium batteries for light EV applications), UL2271 (batteries for light electric vehicles), UL2272 (formerly Hoverboards, now electrical systems for personal e-mobility devices), and UL2489 (electrical systems for e-bikes); however, the applicability of standards in this area varies from product to product. Some products being introduced to the rapidly expanding global micromobility market may not meet all established design and test requirements.

As the relatively new micromobility field continues to evolve, it is critical for manufacturers to thoroughly review adverse environmental and user conditions — particularly surrounding the manipulation and transportation of their products — to assess risks and implement mitigation strategies. When developing micromobility transportation vehicles such as e-scooters, manufacturers may implement more rigorous testing and design protocols that contribute to better understanding among users and public agencies on how to deploy these technologies safely.

How Exponent Can Help

Exponent is a multidisciplinary consulting firm with expertise in numerous aspects of the design, manufacture, and testing of micromobility devices. Our mechanical, materials, and electrical engineering teams have extensive experience evaluating individual components of micromobility devices as well as testing the entire device. These tests are often conducted under both everyday and aggressive use conditions to simulate the stress users may place on devices over the lifetime of the product. Our battery engineers and electrochemists have helped develop and conduct test protocols for accelerated aging studies, cell cycling procedures, and mechanical testing of lithium-ion battery packs used in these devices. We can leverage decades of experience in proper manufacturing practices and failure analysis to help our clients design and manufacture safer, more reliable products.