October 21, 2024

New corporate average fuel economy standards will make EV and hybrid battery technology even more important in the effort to decarbonize

In June, the National Highway Traffic Safety Administration (NHTSA) finalized new Corporate Average Fuel Economy (CAFE) Standards for 2027-2031 model year vehicles sold in the U.S. While the new fuel economy standards aren't as strict as originally proposed in 2023, they will still have significant impact on the automotive industry in the coming years. The new standards require an industry-wide fleet average of approximately 50.4 miles per gallon (mpg) by model year 2031 for passenger cars and light trucks.

To meet those fleet-wide requirements, many manufacturers are choosing to further develop battery technologies for both electric vehicles and hybrid or plug-in drivetrains. Batteries are already playing a crucial role in the future of the automotive sector — but given NHTSA's new fuel economy requirements, they're essential to meeting these fuel economy standards.

Evolving CAFE standards

In the mid-1970s, the OPEC oil embargo caused the price of crude oil to quadruple. In response to this economic shock and increasing environmental concerns, the U.S. government passed the Energy Policy and Conservation Act of 1975 to give NHTSA the authority to regulate motor vehicle fuel economy.

At the time, average new passenger car fuel economy had decreased from 15.9 mpg in 1965 to 13 mpg in 1973. NHTSA set the first CAFE standards for the model year 1978, mandating OEMs meet a target of 18 mpg. CAFE standards rose steadily until 1985, eventually reaching 27.5 mpg for passenger cars. They remained at that level until Congress passed the Energy Independence and Security Act of 2007. NHTSA then increased combined passenger car and light truck fuel economy standards to at least 35 mpg by 2020.

In 2023, NHTSA proposed CAFE Standards of 55.7 mpg for light-duty vehicles and 52.2 mpg for SUVs and trucks. After reviewing thousands of public comments on the proposal, the regulatory agency reduced the CAFE standards to 50.4 mpg for cars and 45 mpg for SUVs and pickups. According to NHTSA, these new fuel economy standards will save almost 70 billion gallons of gasoline and prevent around 710 million metric tons of carbon dioxide from being emitted through 2050.

Electrification to the rescue?

Automakers are allowed to count EVs toward the new CAFE requirements, significantly increasing the average fuel economy of their fleets. To equate EV efficiency to miles per gallon, the industry uses a calculation called the petroleum equivalency factor (PEF). It accounts for EV battery/motor efficiency and electricity sources and delivers an approximate miles per gallon rating — mpg-e. The current PEF calculation gives one electric pickup on the market a rating of 237.7 mpg-e, demonstrating the potential for EVs to drastically increase a manufacturer's average fuel economy against CAFE ratings compared to internal combustion vehicles.

However, in 2023, the U.S. Department of Energy proposed changes to the current PEF calculation to more accurately reflect actual EV efficiency, grid efficiency, and long-term energy usage projections. The proposed PEF would reduce the mpg-e ratings for most EVs by more than 50%, meaning manufacturers will need to produce and sell more EVs to continue improving their CAFE ratings — while also developing new battery technologies and optimizing the performance of existing ones. After receiving feedback from automakers, the Biden Administration approved the new PEF standard but deferred to a gradual transition over the next several years.

Outlook for hybrid technologies

Despite the positive outlook and expected market saturation of EVs in the decades to come, internal combustion engines have become vastly more powerful and efficient over the last 100 years, meaning they — and the hybrid vehicles they power — will continue to have a role in improving fuel economy.

Still, today's gasoline engines achieve around 30% thermal efficiency, meaning only 30% of the fuel energy put in generates useful work that can move the vehicle; the remaining energy is lost primarily to heat and friction. Using technologies like variable-geometry turbocharging, variable valve timing, lean-burn combustion, ceramic coatings, spark-assisted compression ignition, and more, researchers estimate that it's possible for gasoline engines to improve that rate to around 40%. These technologies have potential, but they also add complexity to automobiles, requiring sophisticated development and testing to implement, as well as the possibility of increased costs.

To take advantage of internal combustion engines while also improving fuel efficiency, automakers are likely to increasingly rely on gas-electric hybrid systems to make their vehicles more efficient and meet rising CAFE requirements. Plug-in hybrid vehicles (PHEVs), typically capable of driving 25-50 miles in electric-only mode before the gas-powered engine takes over, are expected to also play a role in improving average fuel economy, though these vehicles will also be subject to the more stringent PEF calculations.

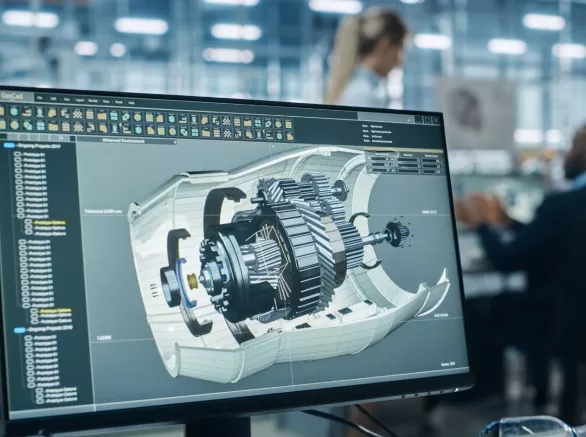

Hybrid vehicles can use smaller combustion engines engineered for peak efficiency, while relying on electric motors at low speeds where gasoline engines are relatively inefficient. Hybrid cars can also recover energy when slowing down, through regenerative braking, storing it in their onboard battery packs. Altogether, hybrids achieve about 40% better fuel economy than their all-gas counterparts. In conjunction with strides in battery technologies, advanced computer control of hybrid drivetrains could unlock even greater efficiencies, making hybrid vehicles increasingly attractive to automakers and consumers, who continue to buy hybrids for their lower cost compared to EVs and to avoid concerns about driving long distances and charging infrastructure.

Opportunities for increased EV efficiency

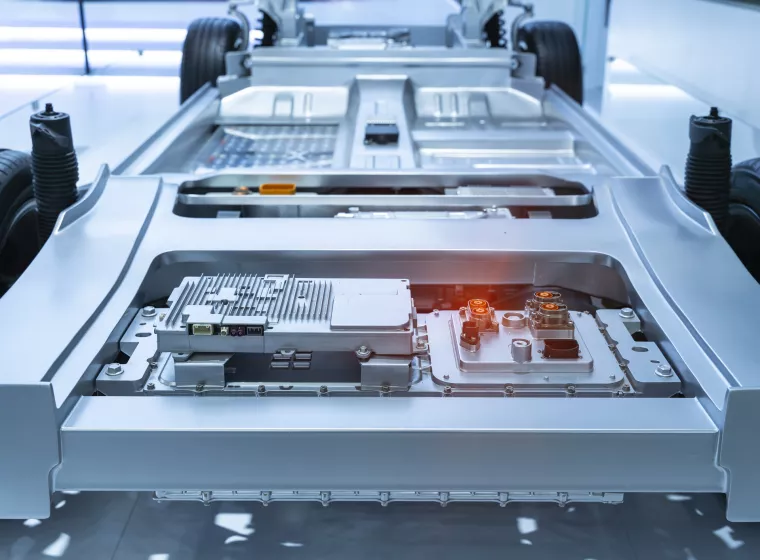

To achieve gains in optimizing EV battery performance, which can also support capturing efficiencies and improvements in hybrid vehicles, many manufacturers are exploring new battery chemistries and technologies, which can offer opportunities to produce lighter weight batteries of higher energy density. Battery weight is critical, as reducing weight increases vehicle efficiency.

One option for weight reduction includes leveraging evolving battery chemistries, e.g., solid-state batteries, which are anticipated to be twice as energy dense compared to traditional batteries. Similarly, silicon-anode batteries also promise increases in energy density, which, in turn, could allow hybrid vehicles to be equipped with smaller, lighter batteries — a key factor in improving efficiency.

However, developing new battery technology takes time and expertise. New battery chemistries can present unique challenges to commercialization at scale, such as introducing new modes of failure as they are exposed to real-world use and environmental conditions. More advanced battery management systems require additional testing for monitoring the battery over time and use in the environment. The resulting new batteries require rigorous additional design evaluation and validation procedures to ensure they are safe for consumer and fleet use.

Cell-to-pack (CTP) manufacturing offers another opportunity to improve EV performance on a quicker time horizon compared to development of new battery chemistries. Compared to traditional designs, CTP options directly integrate battery cells into the pack, eliminating intermediate modules to enhance energy density and simplify manufacturing. As a result, the volumetric density of the battery pack can be significantly enhanced, which can increase overall vehicle efficiency.

Other areas of improvement for batteries include advances in estimating the battery state-of-health (SOH) and state-of-charge (SOC) more accurately. The ability to estimate the health, range, and capacity of battery packs in-vehicle is critical for safe and reliable battery management systems. More accurate measurements of these attributes will require more sensitive electronics, more frequent monitoring, and advanced software algorithms to interpret their data. These advancements are happening in tandem with the development of new battery technologies and testing, which are critical to supporting the safe operation of batteries over their lifespan, as well as ensuring transparency for consumers about the mileage an EV can be expected to offer.

A future with less fuel

NHTSA's latest CAFE requirements may be less stringent than originally proposed, but they still signal a sizeable shift in regulatory requirements that is increasing pressure for automakers to continue developing new battery and EV technologies and optimizing the performance of existing internal combustion technologies.

As automakers make strides toward producing more EVs, the remaining cars in the fleet could include battery-augmented hybrid systems, likely leaving pure fossil-fuel-powered vehicles in the minority. The further development of EVs to meet government fuel economy regulations and help decarbonize the transportation sector is certain, with perhaps greater opportunities for hybrid applications to continue progressing. Both advancements are underpinned by the ability to optimize existing technologies and scale new ones, making batteries and hybrid options more important in transportation than ever before.

What Can We Help You Solve?

Exponent brings decades of failure analysis and quality assessment experience to improving performance and safety for EV batteries and hybrid drivetrains. We provide customized testing solutions for cutting-edge battery technologies, and our state-of-the-art test track, purpose-built for the automotive industry, allows us to perform extensive real-world vehicle and vehicle component testing.