October 25, 2022

A significant uptick in medical devices that use microfluidics means more demand for standardization, safety

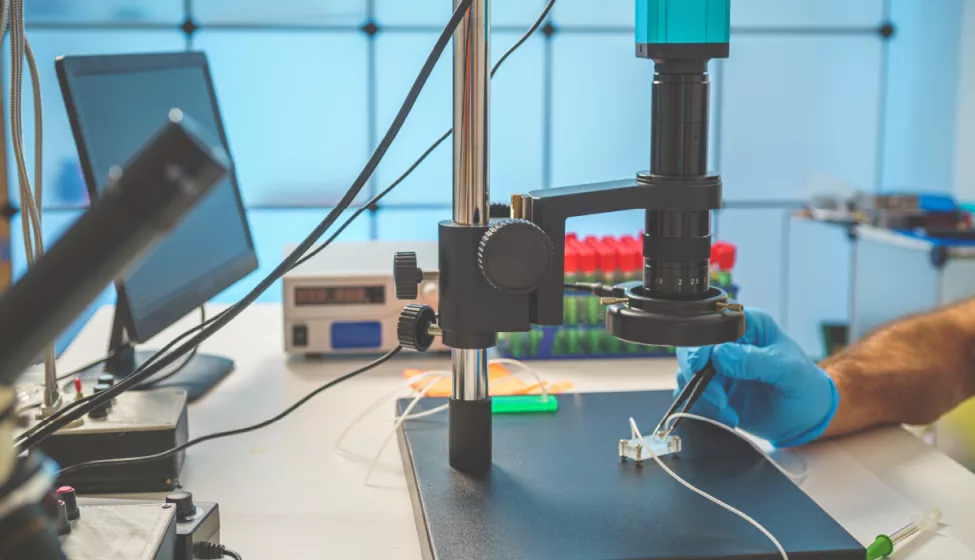

On Sept. 1, according to coverage of the Next Generation Dx Summit by Diagnostics World news, the Food and Drug Administration's Center for Devices and Radiological Health announced the development of a regulatory science tool for leakage testing in microfluidics-based medical devices that could be available as early as 2023. Microfluidic devices have seen steady growth worldwide over the past five years, with the number of medical device submissions to FDA that use microfluidics increasing more than 400% from 2013 to 2018. Device leakage has emerged as an issue that can contribute to device failure.

The objective of leakage testing is to develop test methods and protocols for flow testing of microfluidic devices where there are challenges related to cracks or openings, bubble formation, or channel obstructions. FDA's Microfluidics Program intends to fill knowledge gaps by fostering consistent microfluidic device assessment, development, and innovation.

The Microfluidics Program recently co-authored a journal article reviewing different leakage testing practices in use by industry. The article articulates the benefits of using different test media and material and highlights the utility of leakage testing throughout the total product life cycle. As well, according to Diagnostics World, Rucha Natu, Ph.D., a mechanical engineer in CDRH's Office of Science and Engineering Laboratories, shared during her presentation that "Two years of inter-laboratory studies are expected to be underway between 2023 and 2025, and a standard could be established shortly thereafter."

For device manufacturers, a new FDA testing tool would help guide testing to support regulatory submissions for microfluidics devices, such as those that are becoming more common in in vitro diagnostics (IVD) applications. By standardizing the test methods and protocols required for evaluating microfluidics devices, this tool will not only provide guidance on how testing is to be performed but also the pass/fail criteria and device performance metrics of greatest concern to FDA. This will help guide manufacturers at all stages of product development.

How Exponent Can Help

In the absence of a standard, Exponent can work with manufacturers and FDA to develop custom tests for specific microfluidics devices that will satisfy the testing requirements necessary for regulatory submission. For devices that are still in the design stage, Exponent can work with manufacturers to help guide product development to prepare for successful regulatory submissions and establish appropriate manufacturing quality checks. For devices that are already on the market, Exponent can help manufacturers with issues such as corrective actions and recalls. We currently offer customized testing, which can be augmented to include protocols and insights aligned to standards that support clients in obtaining objective information for their submissions.