May 14, 2020

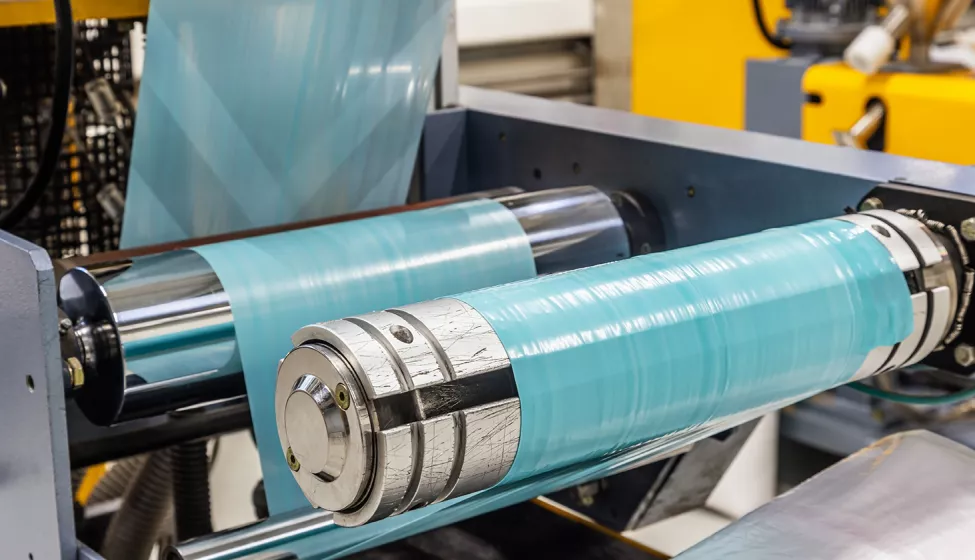

With the global thin film coating market expected to reach an estimated $13.6 billion by 2024,1 thin films have become important elements for product designers in an increasing number of industries, including consumer electronics, energy, and medical devices. While many early applications embedded thin films in encapsulated microchips in stationary devices, today, many thin films are deposited on devices and surfaces that are fully exposed to the outside environment and mechanical abuse. This has introduced a new set of stresses and failures that were not always considered during the initial development of these films. By correctly diagnosing thin film failures, designers can help optimize the quality and reliability of their products and help inform material choice, process design, quality control, and reliability testing.

Thin films are often selected for their special properties, be they electrical, optical, magnetic, or chemical, but for many thin films, structural properties were not of particular concern in their first application. These properties may be poorly understood and not optimized for situations where they sustain mechanical stress. Intuition built on knowledge of bulk-scale properties might not translate well into thin-film contexts, where things like interfacial strength can become a function of the film thickness, or even a function of the adjacent films' properties.

Sometimes, coatings applied to structural elements for their optical or electronic properties can end up carrying surprisingly high loads, particularly when incorporated into adhesive joints between different components. When this happens, films may be selected with no prior consideration of their mechanical properties, and expensive and unwanted mechanical failures can result.

Identifying the origin of failure is critical in any thin film failure analysis. When a thin film cracks or comes off a substrate, the precise point at which the film began to fail may not be immediately obvious. Our team at Exponent has assisted numerous clients to uncover the origin of mechanically induced thin film failures.

By using advanced nanoscale imaging techniques combined with traditional methods of brittle and ductile material fractography, we can often identify a small or even microscopic area where the mechanical fracture or debonding event occurred. Our team can then target the identified origin area with other advanced materials characterization techniques to diagnose the precise nature of the defects or damage that led to failure. If the mechanical failure is precipitated by contamination, handling damage, or process imperfections, it may be possible to minimize the risk of failure by introducing simple changes at the factory. Alternatively, it may be apparent that abuse or use outside of the design intention played a role in the failure.

In cases where failure occurs primarily as a result of stresses which exceed the device's mechanical resilience, we have developed a number of macro-, micro-, and nano-mechanical techniques to assess and quantify the stiffness, hardness, or adhesion of the relevant materials. These analyses can be useful at many stages of the product life cycle, including during prototype development, design qualification, manufacturing, ongoing reliability, and for returns and warranty service.

How Exponent Can Help

Exponent's multidisciplinary team of materials and corrosion engineers and scientists bridges the gap between academic development and industrially relevant problems. By applying academic techniques to the fundamental physics and chemistry of a system, we can diagnose thin film failures and provide design guidance to enhance product quality and performance.